What types of materials are suitable for cutting with the 18mm hardware utility knife

Blade material and performance advantages of the 18mm hardware utility knife

Ningbo Chuangxin's 18mm hardware utility knife is made of high-performance alloy steel. After advanced heat treatment, the hardness usually reaches HRC58 or above, ensuring that the blade has excellent wear resistance and sharpness. The blade thickness is moderate, taking into account both cutting strength and flexibility, and can adapt to a variety of complex cutting environments. At the same time, the blade surface is often equipped with an anti-corrosion coating, which significantly improves the anti-oxidation and anti-corrosion capabilities and extends the service life of the knife.

Material types and application scenarios suitable for cutting

With a sturdy and durable blade structure, the 18mm hardware utility knife can accurately cut a variety of common and special materials, including:

Cardboard and corrugated boxes

In the logistics and packaging industries, the unpacking and cutting of cartons is very frequent. The 18mm blade is sharp and tough, and can quickly penetrate heavy corrugated cardboard to ensure a smooth cut and avoid secondary damage to the goods.

Plastic film and foam materials

Whether in the packaging industry or industrial manufacturing, plastic films and various foam materials require precise cutting. The hardness and sharpness of the blade make it easy to cut all kinds of polyethylene (PE), polypropylene (PP) films, as well as foam materials such as EVA and PU, ensuring neat cutting edges.

Leather and fabrics

The clothing manufacturing and handicraft industries require knives with good cutting control. The 18mm hardware utility knife can effectively cut natural leather, artificial leather and a variety of textile materials to meet the needs of high-quality cutting.

Rubber and sealing strips

Rubber gaskets and sealing strips are often required in mechanical manufacturing and automobile repair. The wear resistance and sharpness of the blade ensure that the cutting process is smooth and not easy to deform, ensuring that the sealing effect is not affected.

Thin wood and plywood

Thin wood is often required in furniture manufacturing and handicraft production. The 18mm hard blade can handle plywood and thin wood with fine fiber structure, and the force is even when cutting to avoid material breakage or splitting.

Aluminum foil and composite materials

The aluminum foil materials in the electronics and packaging industries are extremely thin and fragile. The precision cutting characteristics of the blade ensure that precise openings can be achieved without destroying the integrity of the material. In addition, the cutting of composite materials also requires the tool to take into account both strength and precision, and the 18mm tool performs well.

PVC pipes and soft metal materials

In pipeline installation and maintenance operations, soft plastic pipes such as PVC pipes and aluminum soft metal pipes require efficient cutting tools. Ningbo Chuangxin Cutting-Tool Manufacture Co., Ltd.'s hard blades have sufficient strength to quickly complete cutting work.

What are the characteristics of the handle material and ergonomic design of the 18mm hardware utility knife?

Professional selection of 18mm hardware utility knife handle materials

High-quality handle materials not only determine the durability and feel of the knife, but also directly affect the safety of use and user comfort. Ningbo Chuangxin has selected a variety of high-performance materials in the handle design of the 18mm hardware utility knife:

High-strength ABS plastic

ABS (acrylonitrile-butadiene-styrene copolymer) is widely used in the manufacture of knife handles due to its excellent mechanical strength, impact resistance and heat resistance. Ningbo Chuangxin uses high-quality ABS to ensure that the handle structure is stable and durable, and can withstand the mechanical wear and impact caused by daily high-intensity use.

TPR (thermoplastic rubber) anti-slip coating

To enhance the comfort and anti-slip performance of holding, Ningbo Chuangxin uses TPR material to cover the handle surface. TPR has soft elasticity and good friction coefficient. It can maintain a firm grip even in sweaty or wet conditions, reduce the risk of slipping during operation, and greatly improve safety.

Environmentally friendly materials and sustainable development

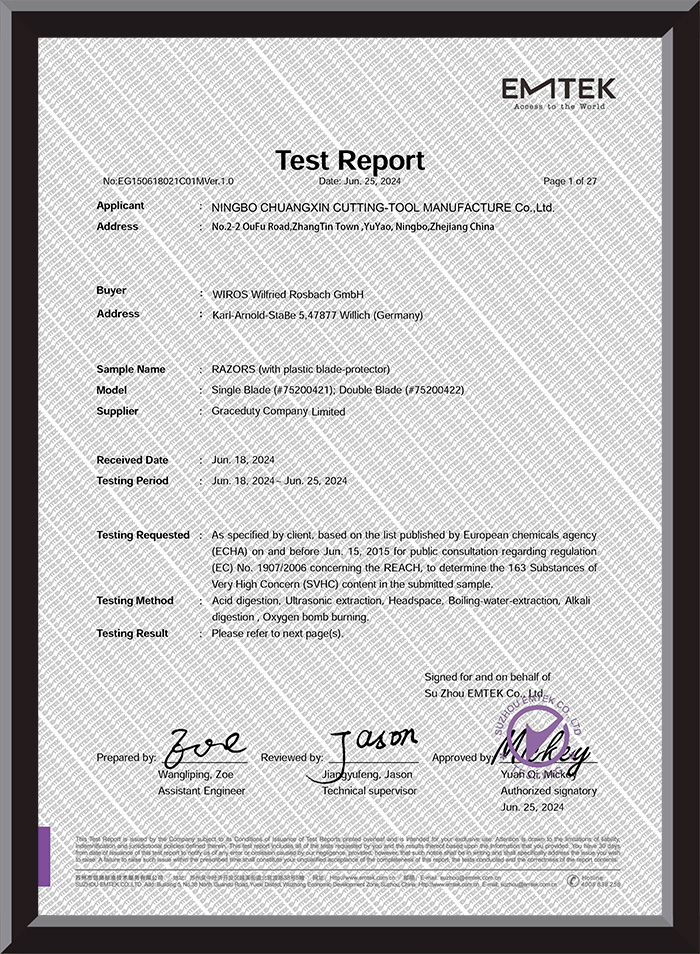

Ningbo Chuangxin Cutting-Tool Manufacture Co., Ltd. pays attention to the concept of environmental protection. The handle materials are in line with international environmental standards, non-toxic and harmless, and meet the certification requirements of ROHS and REACH. At the same time, some handles are made of recyclable materials to promote green manufacturing and sustainable development.

Ergonomic design: conform to the hand structure, improve cutting efficiency and comfort

The application of ergonomic design makes the knife fit the human hand better, reduces user fatigue, avoids hand soreness and discomfort caused by long-term operation, and improves overall work efficiency. Ningbo Chuangxin Cutting-Tool Manufacture Co., Ltd. 18mm hardware utility knife's specific ergonomic design features include:

Streamlined shape that conforms to the natural curve of the palm

The handle design follows the natural curve of the palm, and the handle has a moderate curvature, which can naturally wrap the hand to ensure a stable grip. Whether it is fine cutting or forceful cutting, it can reduce hand pressure and avoid slipping and stinging.

Anti-slip texture and thickened grip area design

The handle surface is equipped with an ergonomic anti-slip texture to increase the friction between the fingers and the handle and improve the grip safety. The thickened grip area design not only increases the comfort of the hand, but also improves the control accuracy and stability of the knife.

Reasonable weight distribution to ensure a sense of balance

The overall weight distribution of the knife has been precisely designed, and the handle part maintains a moderate weight to balance the entire knife, avoiding hand fatigue and control errors caused by uneven weight, and improving cutting accuracy.

Convenient blade replacement button and safety lock design

Ningbo Chuangxin Cutting-Tool Manufacture Co., Ltd.'s 18mm hardware utility knife handle is equipped with an easy-to-operate blade replacement button, which allows quick blade replacement with one hand. The ergonomic design makes the operation smoother and safer. At the same time, the safety lock design effectively prevents the blade from accidentally slipping out during use, ensuring user safety.

English

English 中文简体

中文简体 русский

русский Español

Español