How does the blade width and thickness of a 9mm hardware utility knife affect its cutting ability?

Blade width - the balance between cutting stability and operational flexibility

Blade width refers to the lateral dimension of the blade from one side to the other. Usually, the blade width used by 9mm hardware utility knives is standardized at around 9 mm, which is not only an internationally accepted specification, but also convenient for replacement and compatibility in the market.

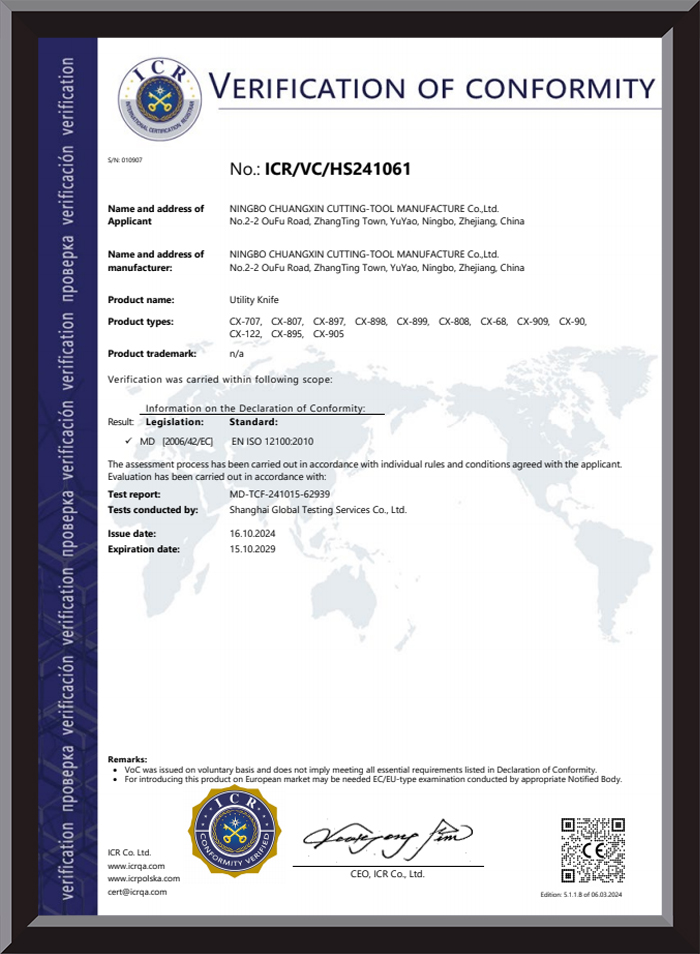

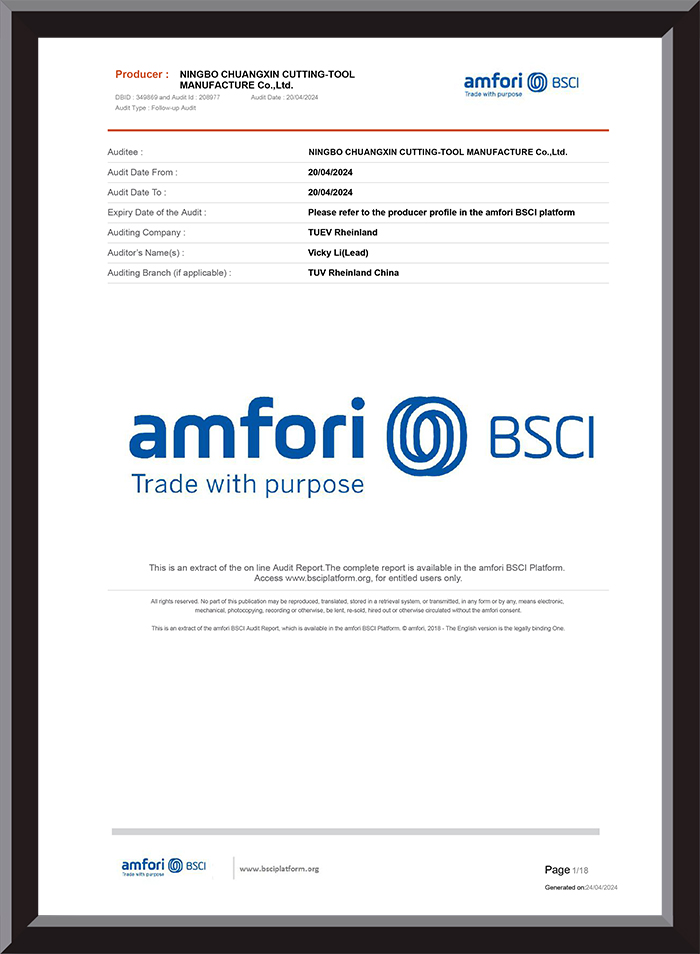

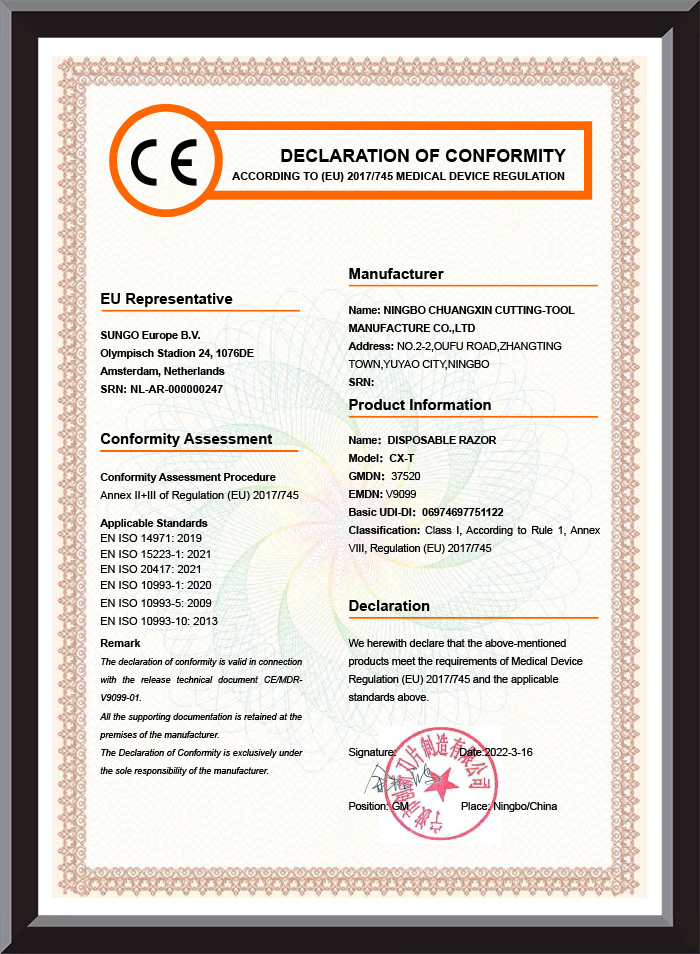

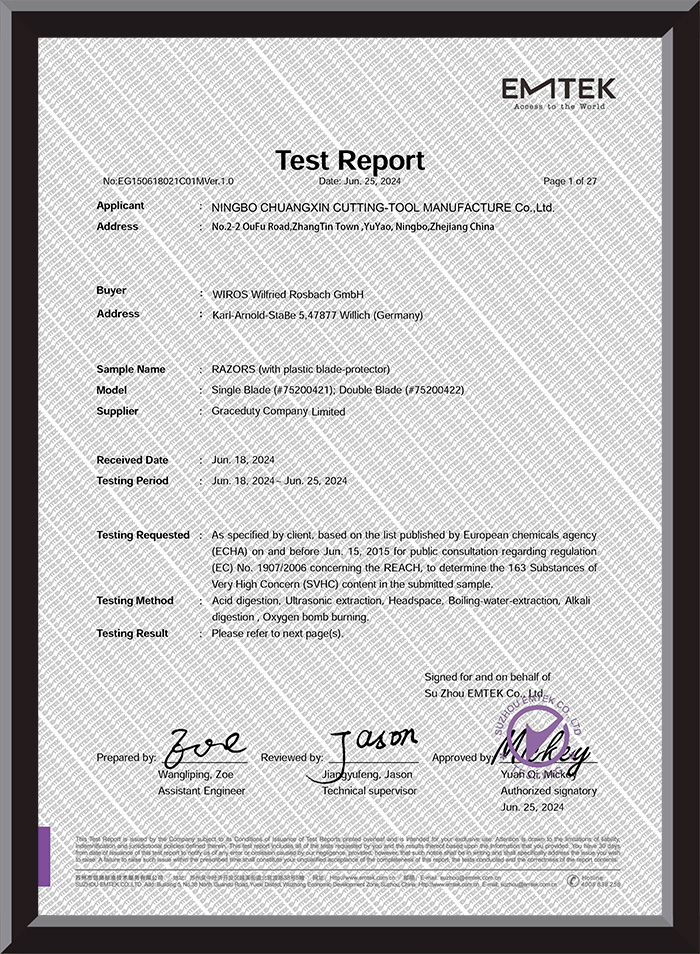

Wider blades usually have stronger lateral stability. In the actual cutting process, wide blades are not easy to bend or twist, and can provide a straighter and more accurate cutting trajectory. This is very important for cutting materials with higher hardness or thickness, such as thick cardboard, leather or plastic boards. For example, Ningbo Chuangxin Cutting-Tool Manufacture Co., Ltd. can ensure that the blade width is within a strict tolerance range through high-precision equipment equipped in its 20,000 square meters modern factory, so as to ensure that each blade can output cutting force stably and avoid cutting deviation caused by blade deformation.

However, wide blades will relatively sacrifice some flexibility, especially when curves or details need to be cut, too wide blades may cause inconvenience in operation. Therefore, for some delicate crafts or office stationery fields, Ningbo Chuangxin Cutting-Tool Manufacture Co., Ltd. has also developed a narrower 9mm blade to meet customers' dual needs for precision and flexibility.

Blade thickness - the key to durability and cutting sharpness

Blade thickness is the longitudinal thickness of the blade, which directly affects the strength and sharpness of the blade. Thicker blades have stronger mechanical strength and stronger resistance to breakage, and are suitable for repeated cutting of heavy or hard materials. The thickness of the blades manufactured by Ningbo Chuangxin is precisely designed and strictly controlled, which not only ensures the toughness of the blade, but also maintains sufficient sharpness.

On the other hand, a blade that is too thick may increase resistance during cutting, making the cutting operation laborious and affecting the smoothness of cutting. Especially when dealing with thin materials such as film and paper, a blade that is too thick will affect the smoothness of cutting. Ningbo Chuangxin's professional R&D team has repeatedly tested blades of different thicknesses, optimized the blade material ratio and heat treatment process, and achieved an ideal balance of durability and sharpness of the blade, improving the user experience.

How does the cutting depth and angle of the 9mm hardware utility knife affect the cutting accuracy?

Cutting depth - the basic guarantee for precise cutting

Cutting depth refers to the maximum distance that the blade penetrates the material during the cutting process. Reasonable cutting depth is essential to ensure that the material is completely divided without excessively damaging the underlying structure. The 9mm multifunctional utility knife produced by Ningbo Chuangxin adopts a precisely designed sliding adjustment structure, allowing users to accurately adjust the cutting depth according to different materials and task requirements.

Too shallow a cutting depth will result in the material not being cut off, and repeated force will not only reduce efficiency, but may also damage the blade or material surface. On the contrary, too deep a cutting depth may cause the cutting to be out of control, damage the bearing material or cause safety hazards. Ningbo Chuangxin has designed the optimal cutting depth range for the 9mm hardware utility knife through rigorous R&D testing, combined with ergonomics and material science, taking into account both accuracy and safety.

In addition, the company's high-standard blade manufacturing process ensures the stability of the blade when adjusting the cutting depth, avoiding the influence of cutting straightness due to blade sliding or shaking. The multi-layer composite blade design further improves the cutting efficiency and depth consistency, allowing users to maintain high accuracy and smoothness when cutting cardboard, plastic film or carpet of different thicknesses.

Cutting angle - the key to cutting trajectory and sharpness

The cutting angle refers to the inclination of the blade relative to the surface of the material being cut. A suitable cutting angle can not only ensure the effective transmission of cutting force, but also minimize material deformation and cutting burrs.

The design of Ningbo Chuangxin's 9mm hardware utility knife blade focuses on the optimization of the cutting edge angle. Usually, the blade angle is set between 30° and 45°. This range has been verified by a large number of experiments and can maintain sharpness while taking into account durability and safety.

Although a too small cutting angle (sharper blade) can easily cut thin materials, it is easy to cause the blade edge to be fragile and the risk of breakage increases. At the same time, it is more difficult to control during cutting, affecting the cutting accuracy. On the contrary, a too large angle reduces the cutting efficiency, increases the cutting resistance, and easily causes the material to be squeezed and deformed, resulting in uneven cutting lines.

Relying on its professional R&D team, Ningbo Chuangxin ensures high-precision control of the blade edge angle through advanced CNC machining and heat treatment processes. Combined with the ergonomic handle design, users can control the cutting angle in the most natural posture, improving the comfort and accuracy of operation.

Synergy of cutting depth and angle

Cutting depth and angle do not exist in isolation, but influence and synergize with each other. Ningbo Chuangxin has developed a scientific cutting parameter recommendation system through the analysis of a large amount of measured data, providing the best cutting depth and angle combination for different materials and usage environments, helping users to achieve efficient and accurate cutting.

For example, when cutting thicker hardboard, appropriately increasing the cutting depth while maintaining a smaller cutting angle can ensure a smooth cut and a clean cross section. For thin materials, it is recommended to reduce the cutting depth and increase the angle to prevent over-cutting and material tearing.

English

English 中文简体

中文简体 русский

русский Español

Español