What are the advantages of scraper blades and what cleaning scenarios are suitable for?

Stable material, improve user experience

The scraper blades produced by Ningbo Chuangxin Cutting-Tool Manufacture Co., Ltd. are usually made of metal materials such as high carbon steel or stainless steel. Through reasonable heat treatment processes, their hardness and wear resistance are improved. The blade surface is flat and the cutting edges are sharp, which facilitates the removal of hard stains and reduces damage to the surface of the cleaned object. In daily cleaning work, the stability of the material can extend the use cycle of the blade and reduce the replacement frequency.

Simple structure and easy to operate

These scraper blades are usually designed in standard universal sizes and can be used with most manual scrapers on the market. The replacement process is simple and fast, and users can complete it without professional tools. Some models are equipped with a quick-removal structure, which is convenient for cleaning and replacing old blades, improving usage efficiency, and is suitable for users who frequently replace blades.

Can be used for treatment of many types of stubborn stains

Scraper blades are often used in scenarios such as kitchen oil stains, stove scorch, ceramic tile surface scaling, glass glue residue, paint residue and other scenes. Its physical scraping method has good removal ability for dry knots and strong adhesion stains. Especially in areas that are difficult to wipe off with a cloth during daily cleaning, the scraper blade can be used as an auxiliary tool to effectively improve cleaning efficiency.

Reasonable blade control to reduce the risk of scratches

The blade design emphasizes the balance between sharpness and safety. Through precision grinding, the blade reaches the cutting standard, while the edge treatment avoids excessive sharpness, reducing the risk of scratching materials when used on surfaces such as glass, stainless steel, and ceramic tile. This design is suitable for users who need to be carefully cleaned but do not want to damage the surface of an object.

Flexible matching, suitable for multiple handles

The scraper blades provided by Ningbo Chuangxin Cutting-Tool Manufacture Co., Ltd. can be adapted to a variety of handles, such as short handles, retractable long handles, rubber handles or styles with angle adjustment functions, to meet the needs of different occasions such as home, commercial, and industrial occasions. Various combinations provide users with more flexible cleaning solutions.

Applicable to multiple scenarios to meet diverse needs

These scraper blades are widely used in homes, offices, shopping malls, hotels, automobile glass repairs, construction sites and other occasions. For example, property cleaning staff can use them to remove tape residues on elevator doors, decoration workers can use them to remove construction glue left on glass, and kitchen staff can use them to scrape off stubborn stains on range hoods and stoves.

Easy to store and carry

Some scraper blades are equipped with plastic storage boxes or sheaths, which are easy for users to carry and store, and avoid accidental injury or blunt blades. This portability provides more convenience for cleaning personnel who need to frequently access different working environments.

Supports bulk procurement and customization services

As an enterprise with more than 30 years of production experience, Ningbo Chuangxin Cutting-Tool Manufacture Co., Ltd. can provide batch procurement and customization services according to customer needs, including adjustments in blade size, material, packaging, etc., and is suitable for targeted cooperation among supermarkets, cleaning companies, and tool brands.

Use with a safe scraper for more peace of mind

Used with scraper tools with anti-slip handles and blade storage structures, it can further improve the safety of use. Some supporting tools also have the function of automatic blade retraction, which can be retracted when not in use, reducing the probability of accidental injury. It is especially suitable for children at home or in public areas.

What material is used to make the scraper blades and is it easy to rust?

The importance of material selection

In the manufacturing of scraper blades, the choice of materials directly affects its service life, corrosion resistance and actual cleaning effect. Based on years of production experience, Ningbo Chuangxin Cutting-Tool Manufacture Co., Ltd. has selected a variety of metal materials with relatively stable performance, striving to balance the safety, durability and practicality of use. Material selection not only affects whether the blade is sharp, but also determines whether it is easy to maintain and whether it is suitable for multi-scenario applications.

Common materials used: high-carbon steel

High carbon steel is a relatively common metal material in the manufacturing of scraper blades. It has high hardness and strong wear resistance, and is suitable for making edges with certain sharpness and compressive resistance. Ningbo Chuangxin Cutting-Tool Manufacture Co., Ltd. The high-carbon steel used in the production of scraper blades is usually heat treated to make it have strong structural stability and is not easy to deform, which is suitable for the removal of stubborn stains.

High carbon steel also has certain restrictions. In humid or acid-base environments, if it is not cleaned and dried in time, rust spots are prone to appear on the surface. Therefore, users need to pay attention to cleaning and maintenance after use to extend the service life of the blade.

Improvement solution: Stainless steel blade

In order to improve the corrosion resistance of the blade in humid environments, the company has also introduced stainless steel material as the material of some models of scraper blades. Stainless steel has good anti-rust properties, especially in high humidity environments such as kitchens, bathrooms, and glass cleaning. Although the stainless steel blade is slightly lower than that of high-carbon steel in terms of hardness, it is more stable and easier to maintain during use.

Stainless steel material is also suitable for commercial scenarios where blade rust is high, such as hotel cleaning, shopping mall glass maintenance, medical cleaning and other fields.

Surface treatment improves rust prevention capability

To further improve the anti-rust performance of the blade, Ningbo Chuangxin Cutting-Tool Manufacture Co., Ltd. has surface coating treatment for some high-carbon steel blades. Common treatment methods include nickel plating, chrome plating or adding anti-rust oil film. Although this type of treatment will not completely eliminate rust, it can effectively delay the oxidation speed of the blade during daily use, and is suitable for home or office use scenarios where there are moderate requirements for rust prevention.

In daily applications, these treatments provide users with more weather resistance options, especially for humid climates in the south or more frequently used environments.

Whether the blade is prone to rust: depends on the material and maintenance

Whether it is prone to rust is mainly related to the material of the blade itself, the surface treatment process and the maintenance method after use. If high-carbon steel blades are not dried in time, rust spots may appear in a short period of time; while stainless steel blades are less likely to rust, but they will also be affected if they are exposed to corrosive substances for a long time.

It is recommended that users use a dry cloth to wipe the blade surface in time after use and store it in a ventilated and dry place. For blades that are not used for a long time, a small amount of anti-rust oil can be applied for sealing and storage.

Material selection and usage scenario matching

Ningbo Chuangxin Cutting-Tool Manufacture Co., Ltd. provides scraper blade options of different materials according to different cleaning tasks and use locations.

If used in kitchen, bathroom or damp glass cleaning environments, it is recommended to choose stainless steel blades.

If used in situations where the edge strength is high, such as floor glue stains and wall residues, high-carbon steel blades can be considered and maintenance after use. The company has marked the blade material in the product label or description, which is convenient for users to choose and purchase on demand.

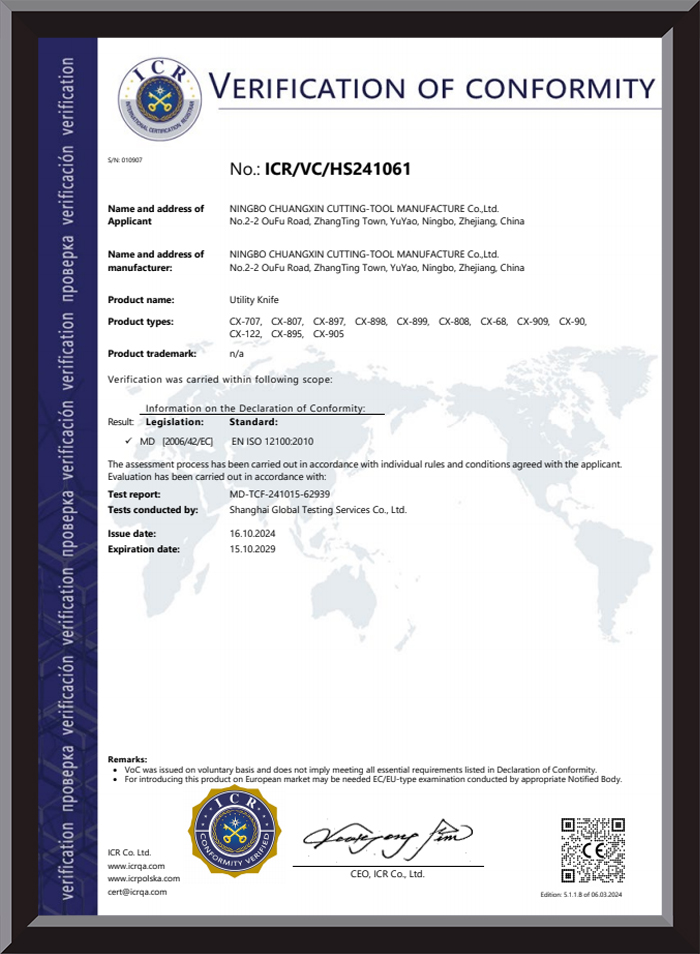

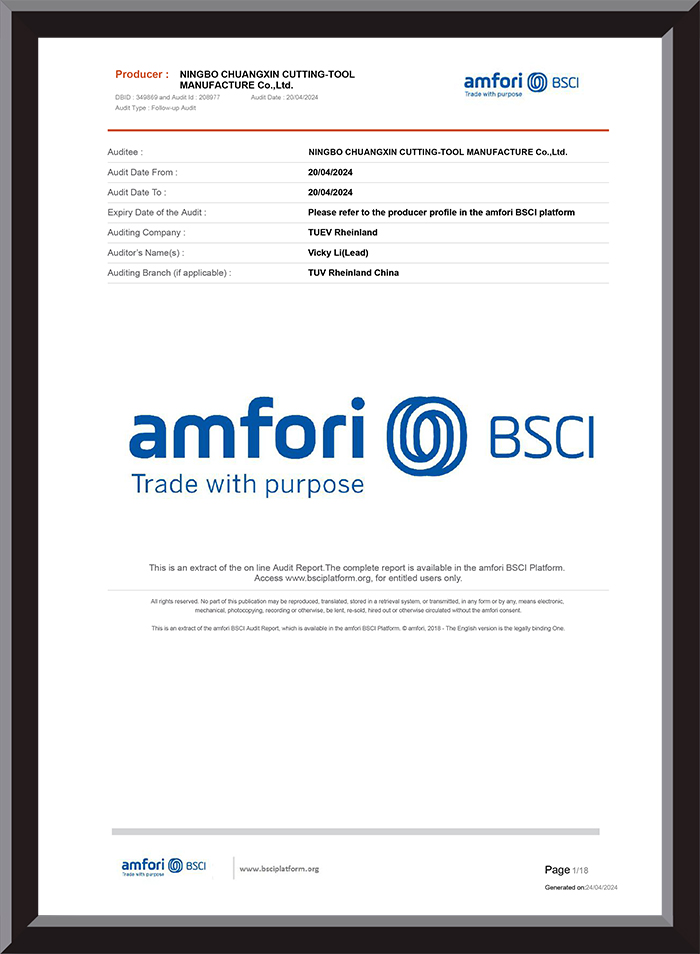

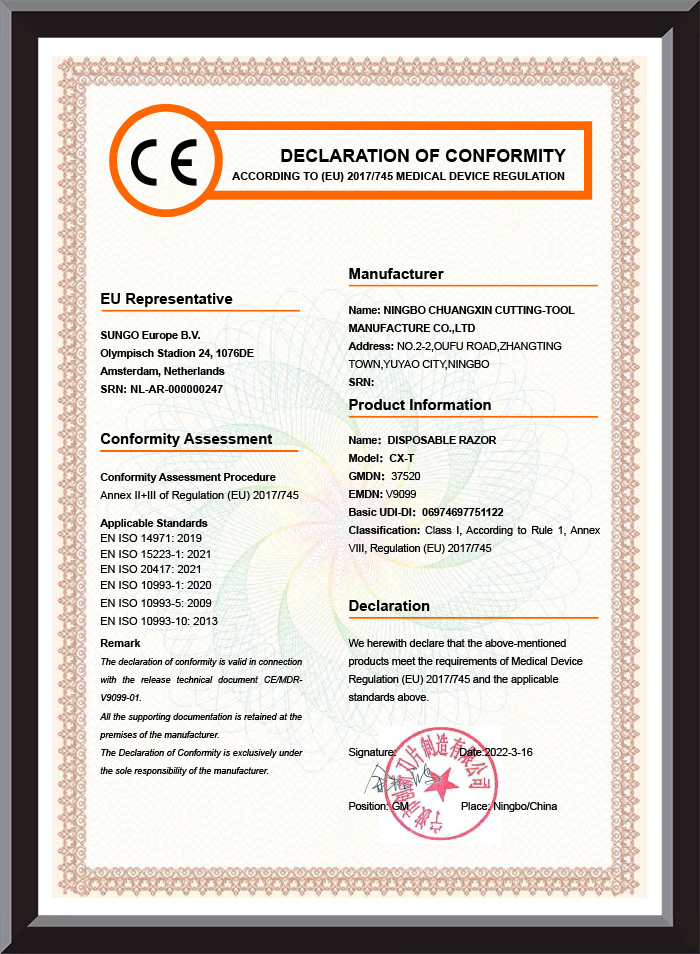

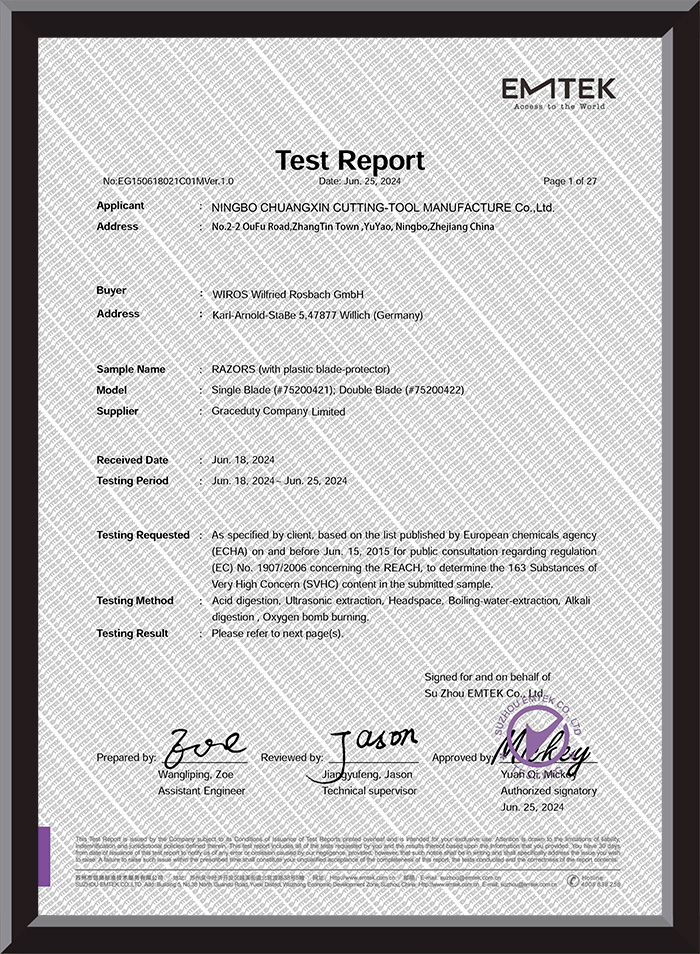

Quality control and standard manufacturing process

Ningbo Chuangxin Cutting-Tool Manufacture Co., Ltd. has more than 30 years of manufacturing experience and has established a relatively complete standard process in the procurement of raw materials, processing accuracy and factory inspection of scraper blades. The company's professional technical team analyzes and screens each batch of raw materials to ensure the stability of the raw materials; at the same time, the finished product needs to undergo multiple inspections, including corrosion resistance test, hardness test and sharpness test to ensure that the product can meet the requirements of different cleaning purposes.

Material and maintenance jointly determine durability

Whether the scraper blade is prone to rust depends not only on the manufacturing material, but also on the user's use and maintenance method. Ningbo Chuangxin Cutting-Tool Manufacture Co., Ltd. provides users with a variety of choices suitable for different environments through a variety of material selection and processing technology. When purchasing, users should judge the blade type based on their own usage scenarios and maintain it reasonably during use to obtain more stable performance and a longer service life.

English

English 中文简体

中文简体 русский

русский Español

Español