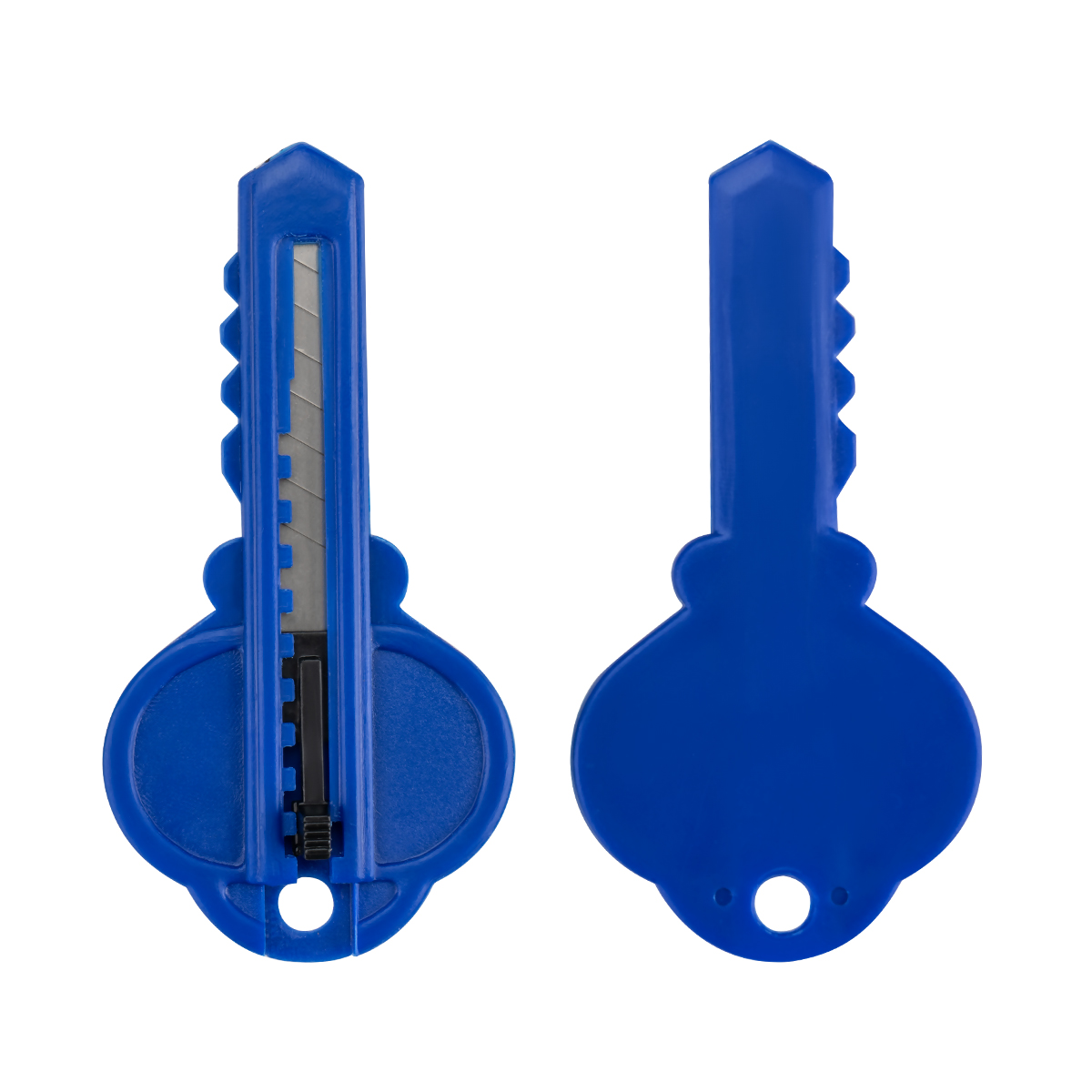

What are the safety design characteristics of Ningbo Chuangxin’s safety utility knife?

Design background for safety utility knife

Ningbo Chuangxin Cutting-Tool Manufacture Co., Ltd. has been committed to the research and development and manufacturing of a variety of razor and utility knife products since its establishment in 1993. In the field of safe tool knife, the company has designed a series of products that focus on safety in the field of safety, combining years of production experience and market demand to ensure that users can be effectively protected during operation. Safety design not only reflects the attention to user health, but also shows the company's emphasis on product quality.

Anti-slip handle design

The handle of the safety tool is ergonomic, and the material is made of rubber or plastic materials that are wear-resistant and anti-slip. The handle surface has been carefully processed and has good friction, which can effectively reduce the risk of slippage in the hand during use. Whether in humid environments or during long-term operation, users can maintain a stable grip feeling to reduce damage caused by accidental slips.

Blade locking mechanism

In order to prevent the blade from accidentally slipping out during use, Ningbo Chuangxin's safety utility knife is equipped with a variety of locking mechanisms, including push-pull locking, knob locking, etc. These mechanisms can be securely secured when the blade is fully extended or retracted, preventing the blade from loosening due to vibration or improper operation. The blade locking function ensures the stability of the blade and provides users with a safer usage environment.

Convenient and safe blade replacement method

The safety utility knife is designed with full consideration of the convenience and safety of blade replacement. The blade replacement process usually does not require direct touching the blade with your hands. Most models complete the removal and installation of the blade through pressing or sliding devices. This design effectively reduces the risk of users being cut when changing the blade, while shortening the replacement time and improving work efficiency.

Blade sheath and storage safety

Some safety tool knives are equipped with removable blade sheaths to protect the blade sharpness and prevent accidental damage when not in use. The sheath is usually made of durable plastic for easy carrying and storage. In addition, the overall structure of the tool is compact, which makes it convenient for users to safely place the tool in the tool box or storage box to avoid causing damage during handling.

Stable blade design

The blade part of the safety utility knife is made of high-strength materials, and the structure is strong and durable. By optimizing the internal structural design, the blade has good compression and bending resistance, reducing the possibility of tool deformation or damage during cutting. The stable blade not only improves the safety of use, but also extends the service life of the product.

Visual safety tip design

Some safety tool designs have added color partitions or logo prompts, such as red warning bars or blade protruding length markings to remind users to pay attention to operational safety. This visual safety prompt helps users stay alert when using it and reduce the risk of misoperation.

Adapt to various operating environments

Ningbo Chuangxin's safety tool knife is suitable for use in a variety of industries, from office stationery to hardware tools, and can meet the safety needs of different environments. Whether it is warehousing logistics, packaging cutting, or process production, the safe utility knife can provide users with a stable operating experience and protection.

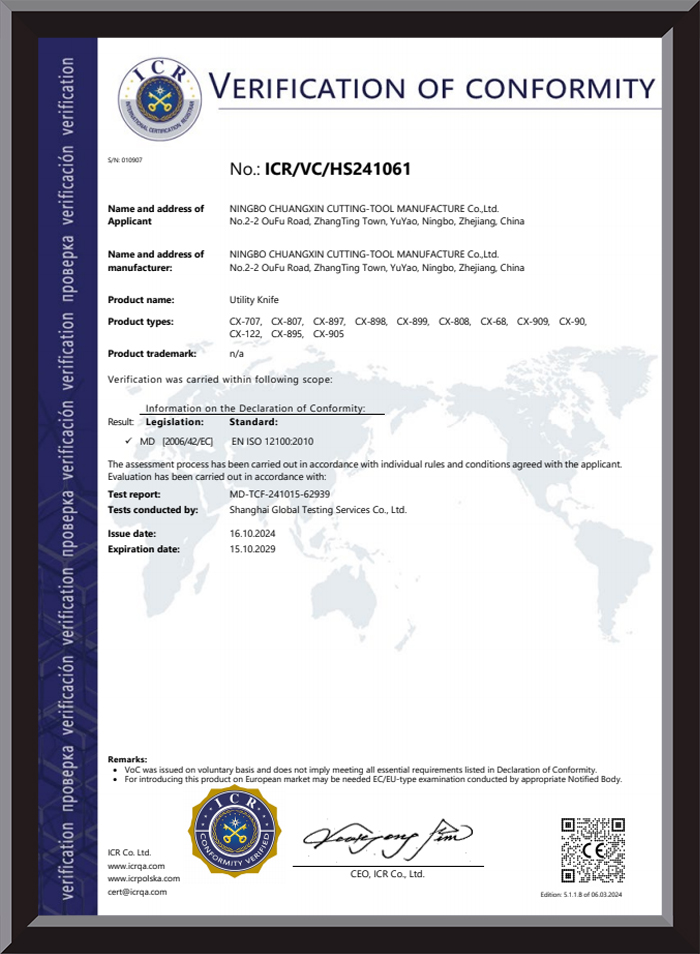

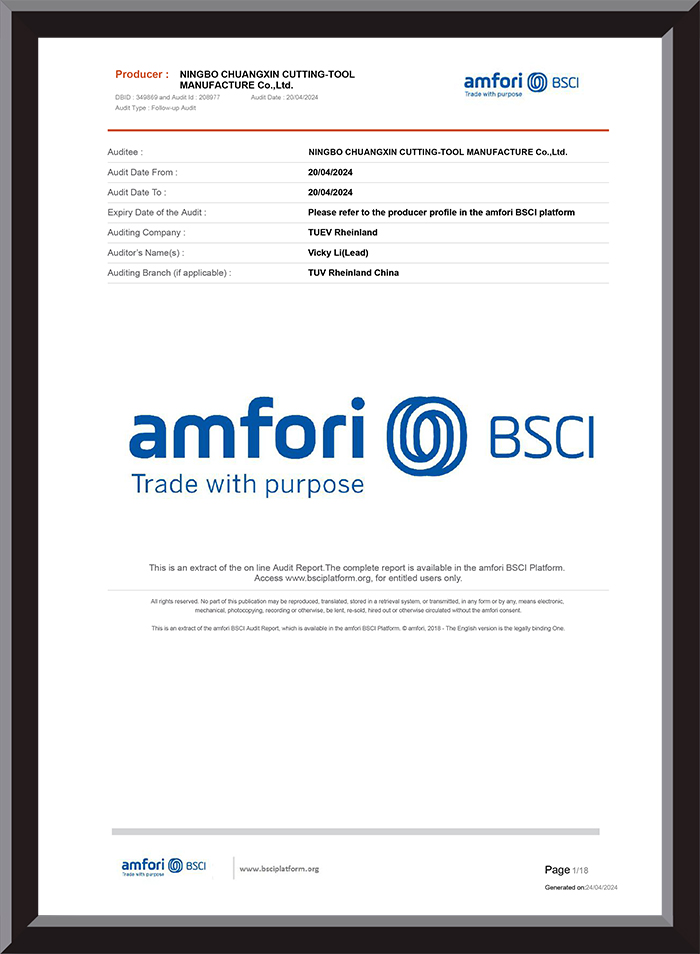

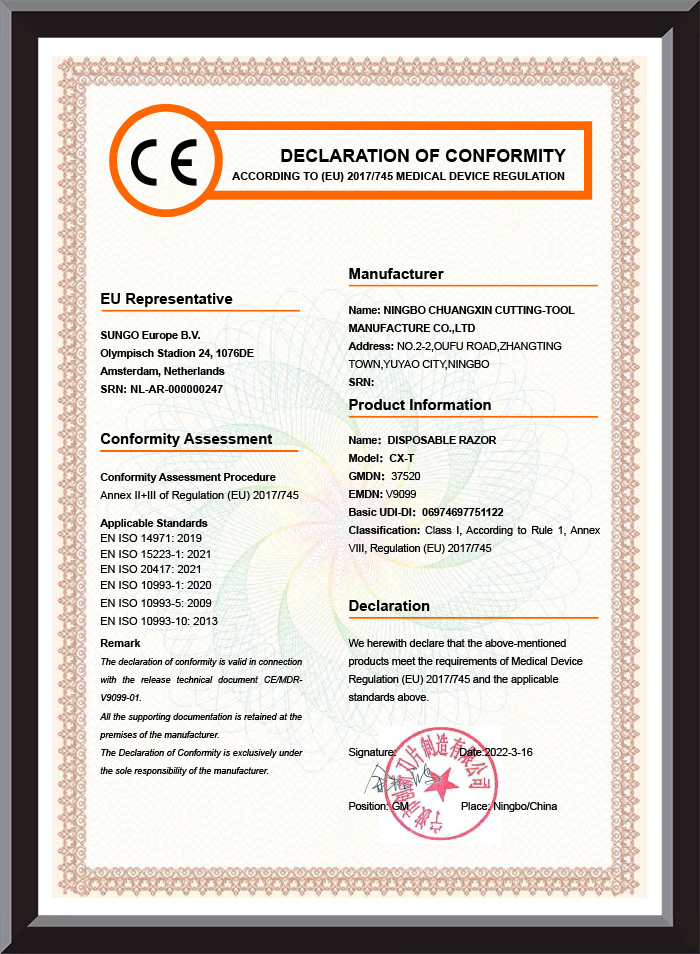

Continuously improved safety standards

As an enterprise with a rich production history, Ningbo Chuangxin Cutting-Tool Manufacture Co., Ltd. continues to pay attention to the update of relevant international and domestic safety standards, and continuously optimizes product design in combination with customer feedback. The research and development process of safety utility knife focuses on details to ensure that each product complies with industry safety specifications and the actual needs of users.

Is it easy to replace the blade of the safety utility knife and are there protective measures to avoid injury?

The importance of blade replacement design

Since its establishment in 1993, Ningbo Chuangxin Cutting-Tool Manufacture Co., Ltd. has been committed to providing a variety of utility knife products, among which the design of safety utility knife focuses on the convenience and safety of user operations. As a consumable and critical part of the utility knife, whether the replacement process is convenient and safe directly affects the user experience and work efficiency. A reasonable replacement design can effectively avoid accidents such as cuts during the replacement of the blade, improving overall work safety.

Convenient and quick replacement mechanism

The blade replacement method of the safety utility knife has been optimized many times, and the sliding, pressing or rotating structural design is generally adopted to simplify the disassembly and installation process. When changing the blade, users do not need to use additional tools to easily disassemble and assemble the blade. Some models are designed with a one-click release button. The old blade can automatically pop up by pressing the button, which facilitates quick replacement of new blades, saving operating time and reducing operation difficulty.

Protective design that avoids direct contact with the blade

Ningbo Chuangxin's safe utility knife pays attention to protective details during the blade replacement process to reduce the possibility of users directly contacting sharp blades. Many products have designed special blade replacement notches, and users can disassemble and assemble by clamping non-sharp parts. The blade part is safely wrapped or covered to avoid accidental scratches on your fingers. Such protective measures effectively reduce the risk of injury during replacement and ensure the safety of the user's hands.

Built-in safety locking device

After the blade replacement is completed, the built-in locking device of the safety tool will automatically fix the blade position to prevent the blade from loosening or sliding out during use. This design not only ensures stability during cutting, but also provides reliable snap support during replacement, ensuring that the blade can only be used after it is properly installed and avoids accidents caused by the incorrect fixation of the blade.

Cooperation between marking and operating instructions

In the design of safe utility knife products, Ningbo Chuangxin combines clear logos and operation guidelines to provide users with more intuitive replacement steps. The replacement process is listed in the product packaging and instructions in detail. Some tools themselves also have replacement prompts to help users quickly master the correct operating methods and reduce risks caused by misoperation.

Blade storage and processing safety

For the replaced discarded blades, some safety tool knives have designed special storage tanks or recycling boxes to facilitate safe storage of discarded blades and avoid the safety hazards caused by random discarding. Users can centrally manage waste blades to reduce the risks of accidental scratches and environmental pollution. This design reflects Ningbo Chuangxin's dual concern for product safety and environmental protection.

Applicable to multiple blade specifications

Ningbo Chuangxin's safety utility knife is compatible with a variety of standard size blades, and users can choose the appropriate blade model according to different needs. The replacement mechanism is adapted to multiple specification blades to maintain consistency and convenience of the replacement process, while ensuring the effective implementation of safety protection design and adapting to cutting needs in different scenarios.

A wide range of people and scenarios

The blade replacement design of the safety utility knife fully takes into account the needs of different users, including professional workers, office workers and home users. Whether it is packaging cutting, handmade or daily repair, blade replacement can be easily completed. The simplified replacement process and protection design lower the user's usage threshold and improves overall security.

Production technology and quality assurance

As an enterprise with more than 30 years of production experience, Ningbo Chuangxin Cutting-Tool Manufacture Co., Ltd. relies on an experienced professional and technical team to strictly control the production process and material selection in the design and manufacturing of safety tool knives. The durability and reliability of the blade replacement device have been tested multiple times to ensure that users maintain a good operating experience and safety during long-term use.

English

English 中文简体

中文简体 русский

русский Español

Español