Single Edge Industrial Utility Blades

The heavy-duty scraping and slitting specialist. Reinforced steel back and SK5 high-carbon edge for maximum rigidity and industrial strength.

Related Products

Explore our sustainable product range

Product Introduction

Redefining personal care with circular economy principles

The Single Edge Industrial Utility Blades are the heavy-duty workhorses of the professional maintenance, automotive, and glass industries. While double-edge blades focus on grooming, the single-edge blade is designed for High-Pressure Scraping and Precision Slitting. Featuring a reinforced steel spine (back), these blades provide the rigidity required to remove industrial adhesives, paint overspray, and decals from flat surfaces without the blade flexing or breaking. For 30 years, our manufacturing facility in Ningbo has been a world leader in single-edge blade production, mastering the specialized process of "back-wrapping"—where a folded metal sleeve is permanently crimped onto the non-sharp edge. This spine not only adds structural strength but also makes the blade safe to handle and compatible with a wide range of industrial scrapers and specialized cutting tools. We use high-carbon SK5 steel, ground to a robust 60-degree angle to ensure the edge is tough enough to resist dulling when used against hard glass or metal surfaces.

Technically, our single-edge blades are engineered for Durability and Safety. Each blade undergoes a specialized tempering process that prevents the steel from becoming brittle, allowing it to withstand significant lateral force. The edge is precision-honed and then coated with a dry-film lubricant to reduce friction during scraping tasks. A key innovation in our production line is the Micro-Crimp Spine. We utilize high-pressure hydraulic presses to ensure the aluminum or steel back is perfectly aligned with the blade, preventing any "blade-slip" during heavy-duty use. For the automotive and painting industries, we offer "Non-Scratch" versions where the blade edge is ground to a specific micro-radius to remove material while protecting the underlying substrate. Our factory is fully ISO 9001 certified, and we employ automated optical inspection to ensure that the spine is centered and the edge is free from burrs or irregularities, which is critical for smooth scraping performance.

For industrial supply distributors, hardware wholesalers, and automotive repair chains, our Single Edge Industrial Blades represent an essential high-volume SKU. We understand the logistics of high-use consumables; therefore, we provide these blades in a variety of industrial packaging formats, including Bulk 100-Blade Safety Sliders and individually wrapped units for retail. Our massive production capacity allows us to offer unbeatable factory-direct pricing while maintaining the quality standards of premium global brands. We also offer full OEM customization, including custom-colored spines for brand differentiation and private-label packaging. Whether you are supplying professional window cleaners or industrial gasket manufacturers, our blades provide the rugged, reliable performance that industrial environments demand. Choosing our single-edge series is a choice for 30 years of manufacturing reliability. We provide the structural strength, the precision edge, and the high-volume supply chain to keep your customers' industrial projects on track.

Ergonomic Design & Natural Texture

Specifications & Quick Facts

| Blade Material | SK5 High-Carbon Industrial Steel |

| Spine (Back) Material | Capped Aluminum or Cold-Rolled Steel |

| Edge Type | Single-Bevel Heavy-Duty Scraper Hone |

| Hardness | 58-60 HRC |

| Standard Size | #9 or #12 Industrial Standard |

| Coating | Dry-Film Lubricant / Anti-Rust Oil |

| Safety Standard | ANSI Z35.1 Compliant Design |

MOQ (Minimum Order)

100,000 PCSLead Time

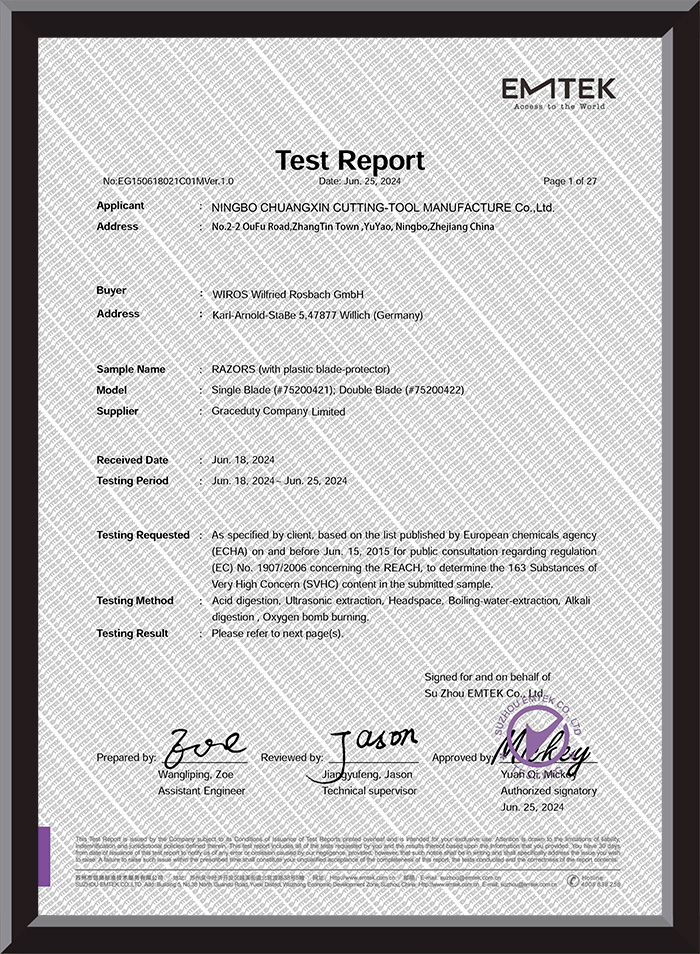

20-25 DaysCertifications

ISO9001, REACH, GSPayment Terms

T/T, L/C, Trade AssuranceOur Customization Services

Comprehensive solutions tailored to your brand requirements

Need more customization options? Contact our engineering team for specialized solutions.

Why Choose Our Razor?

Key benefits for your business and customers

Reinforced Spine

Steel back prevents blade flex, ensuring maximum scraping pressure.

Safe Handling

Spine provides a safe area to grip for tool-free blade changes.

Universal Fit

Fits all standard industrial scrapers and single-edge cutters.

High Leverage

Ideal for removing paint, decals, and industrial adhesives from glass.

SK5 Toughness

Industrial carbon steel holds its edge against abrasive surfaces.

Bulk Efficiency

Safety-slider dispensers allow for fast, high-volume blade access.

Application Scenarios

- Professional Window and Glass Cleaning

- Automotive Decal and Adhesive Removal

- Industrial Painting and Decorating Prep

- Precision Hand-Slitting in Textile and Paper

- Hardware Retail and Professional Trade Supply

Packaging Solutions

We offer Hard-Case 100-Pack Dispensers for workshops and 10-Pack Retail Blisters. For large industrial users, we provide bulk 1000-pack cardboard boxes.

Technical Details & Safety

Manufacturing Process

Blades are stamped and ground, then fed into an Automated Back-Capping Line where the spine is crimped with over 5 tons of pressure.

- Adhesion Testing: Spine is tested to ensure it cannot be pulled off the blade.

- Edge Sharpness: Verified via optical profile projectors.

- Tempering: Heat-treated to ensure the perfect balance of hardness and flex.

Safety & Maintenance

- Always use a scraper tool for large tasks; do not use the blade by hand.

- When scraping glass, keep the blade wet to prevent scratching.

- Change the blade as soon as the edge begins to chip to avoid surface damage.

- Store in a dry place; high-carbon steel can rust if exposed to moisture.

Frequently Asked Questions

The #9 is the standard 0.009" thickness for general use; the #12 is 0.012" thick for heavy-duty scraping.

If used at a shallow angle with a lubricant (soapy water), these blades are standard for glass cleaning.

We offer both; aluminum is standard, while steel is used for high-pressure industrial applications.

In our dispensers, the blades are stacked with the sharp edge protected by the container wall.

Yes, for high-volume orders, we can provide powder-coated or anodized spines in your brand color.

Related Tags

Explore more insights and resources

English

English 中文简体

中文简体 русский

русский Español

Español