Dual-Edge Razor Blade Refill (Bulk)

Barber-grade precision for every shave. Triple-ground Swedish steel with a platinum coating for maximum longevity and smoothness.

Related Products

Explore our sustainable product range

Product Introduction

Redefining personal care with circular economy principles

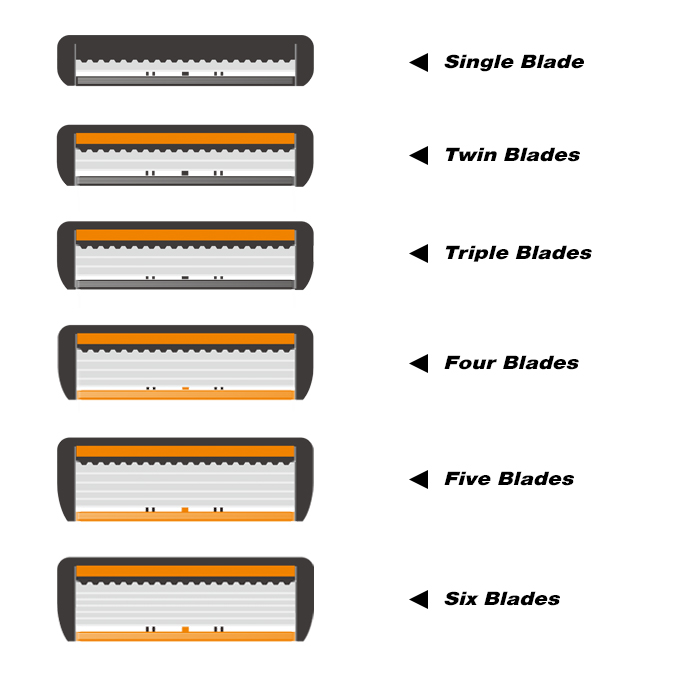

In the foundational layer of the global shaving industry, the Dual-Edge Razor Blade Refill remains the most essential and widely consumed component. While handles and systems evolve, the quality of the individual blade edge is the ultimate determinant of a shave's success. Our facility in Ningbo has spent 30 years perfecting the metallurgical art of blade production, becoming one of China’s leading exporters of high-performance replacement blades. We understand that a razor blade is a technical marvel hidden in a simple strip of steel. The engineering required to take a raw coil of stainless steel and transform it into an edge that is microscopically sharp yet structurally stable is immense. Our blades are manufactured from High-Carbon Swedish Stainless Steel, a material selected for its perfect balance of hardness and flexibility. A blade that is too hard will be brittle and snap; one that is too soft will dull instantly. Our proprietary heat-treatment process achieves a Rockwell hardness that ensures the edge remains sharp for multiple shaves while maintaining the safety of the user.

The manufacturing journey of our dual-edge blades involves a specialized Triple-Grinding Sequence. Most generic blades are ground once or twice; ours are ground three times to create a "Gothic Arch" profile. This shape provides maximum support at the base of the edge while tapering to an extreme sharpness at the tip. After grinding, the blades undergo a multi-stage coating process in high-vacuum chambers. We first apply a layer of Chromium for intense corrosion resistance, ensuring the blade doesn't rust in the bathroom. This is followed by a Platinum sputtering to increase edge durability, and finally, a layer of anti-friction Teflon (PTFE). This Teflon coating is crucial; it reduces the "drag" on the skin, allowing the blade to slice through hair with minimal effort and zero pulling. Every single blade we produce is subjected to a Laser-Sensing Quality Check. Our automated systems scan for microscopic burrs or inconsistencies in the edge, ensuring that every refill pack delivered to our B2B partners is of a professional, "Barber-Grade" standard. This consistency is why our blades are trusted by millions of users in both the consumer safety razor market and the professional barber industry.

For wholesalers, distributors, and private label brands, our bulk razor blade refills offer the highest volume-to-value ratio in the industry. We provide a massive range of packaging options, from the traditional 5-blade "Tuck" (wax-paper wrapped in a small cardboard box) to 100-blade "Master Packs" and industrial bulk quantities for surgical kit manufacturers. We also offer specialized Private Labeling Services, where we can print your brand logo directly onto the steel blade using high-precision ink or laser marking. Our facility’s scale allows us to produce millions of blades per month, ensuring a stable supply for even the largest global contracts. As the world shifts toward sustainable, plastic-free grooming, the demand for double-edge blades is accelerating. By partnering with us, you are accessing 30 years of manufacturing expertise and a product that is 100% recyclable and ecologically sound. We are committed to a future of precision and reliability, ensuring that every blade we produce delivers the perfect cut. Whether for a classic safety razor, a barber’s shavette, or an industrial application, our dual-edge refills are the standard of excellence in the global market.

Ergonomic Design & Natural Texture

Specifications & Quick Facts

| Material | Swedish High-Carbon Stainless Steel |

| Edge Profile | Triple-Ground Gothic Arch |

| Coating 1 | Chromium (Anti-Corrosion) |

| Coating 2 | Platinum (Edge Strength) |

| Coating 3 | Teflon / PTFE (Anti-Friction) |

| Thickness | Standard 0.10mm Precision Edge |

| Compatibility | All Standard Safety Razors & Shavettes |

MOQ (Minimum Order)

500,000 BladesLead Time

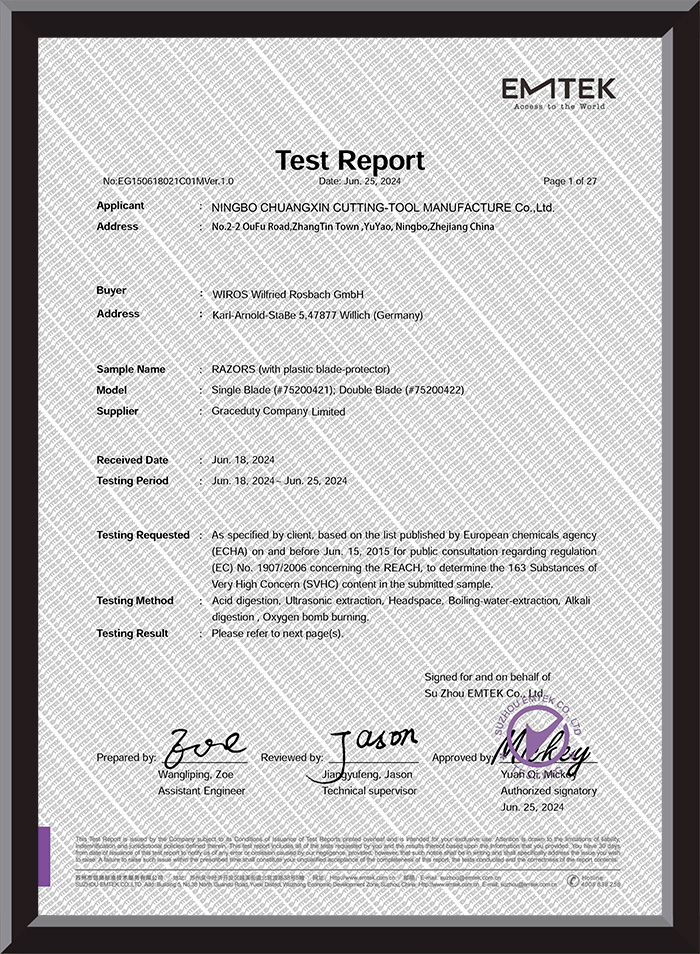

20-30 DaysCertifications

ISO9001, REACH, SGSPayment Terms

T/T, L/C, PayPalOur Customization Services

Comprehensive solutions tailored to your brand requirements

Need more customization options? Contact our engineering team for specialized solutions.

Why Choose Our Razor?

Key benefits for your business and customers

Barber-Grade Sharpness

Triple-honing process ensures a clean, tug-free cut every time.

Extended Life

Platinum coating allows for 5-7 comfortable shaves per blade side.

Universal Fit

Standard dimensions fit all classic safety razors and shavettes globally.

Zero-Drag Glide

Vacuum-applied Teflon coating minimizes skin friction and irritation.

Eco-Friendly

100% recyclable steel; the perfect alternative to plastic cartridges.

Custom Branding

Logo printing available directly on the blade for private labels.

Application Scenarios

- Professional Barber Shop and Salon Supplies

- Personal Care and Pharmacy Retailers

- Eco-Friendly and Zero-Waste Lifestyle Brands

- Industrial and Surgical Tool Manufacturers

- Subscription Razor Blade Services

Packaging Solutions

We offer 5-Blade Wax Paper Tucks, 100-Blade Hanging Cards, and Industrial Bulk Sleeves. All inner packaging is moisture-resistant. Custom cardboard box printing is available.

Technical Details & Safety

Manufacturing Process

Blades are produced from Continuous Steel Strips in a fully automated line. Includes Cryogenic Tempering to stabilize the molecular structure of the steel edge.

- Laser Inspection: 100% scanning of edges for microscopic imperfections.

- Anti-Rust Oiling: Food-grade mineral oil coating for long shelf life.

- Precision Sputtering: Uniform thickness of Platinum and Teflon coatings.

Safety & Maintenance

- Handle blades by the short ends only; never touch the sharp edges.

- Store in original wax paper until use to prevent oxidation.

- Use a dedicated "Blade Bank" or sharps container for safe disposal.

- Ensure the blade is centered perfectly when loading into a safety razor.

Frequently Asked Questions

Yes, individual safety blades are generally ground to a finer edge than the blades inside a cartridge.

Each blade is individually wrapped in moisture-proof wax paper to ensure it arrives in perfect condition.

They can be used in "Shavette" style razors where the blade is snapped in half or inserted whole.

If kept in their original wax paper and in a dry place, they have a shelf life of over 10 years.

Yes, they are made of pure stainless steel and are 100% recyclable in metal scrap streams.

We primarily offer platinum stainless, but can produce black-oxide coated blades for specialty orders.

Custom blade printing typically starts at 500,000 blades.

Yes, the Swedish steel and triple-grinding make them excellent for coarse and thick facial hair.

We use laser-reflection technology to monitor the edge geometry on the production line in real-time.

Yes, they follow the international standard dimensions for double-edge razor blades.

Related Tags

Explore more insights and resources

English

English 中文简体

中文简体 русский

русский Español

Español