Single Sided Medical Prep Razor

Surgical-grade precision for pre-operative skin preparation. Trusted by hospitals and clinical professionals worldwide for safety and efficiency.

Related Products

Explore our sustainable product range

Product Introduction

Redefining personal care with circular economy principles

In the highly demanding environment of surgical theaters and clinical wards, the Single Sided Medical Prep Razor is an indispensable tool that bridges the gap between patient safety and procedural efficiency. For over three decades, our manufacturing facility has specialized in the production of high-precision cutting instruments, and our medical line represents the pinnacle of this expertise. Pre-operative hair removal is a critical step in surgical site preparation, directly impacting the risk of Surgical Site Infections (SSIs). Our medical prep razors are engineered with a singular focus on skin integrity. Unlike standard consumer razors, the geometry of our medical blades is optimized to shave hair flush with the skin surface without causing the micro-abrasions that can harbor bacteria. This is achieved through the use of ultra-fine Swedish stainless steel, triple-honed to a specific edge tension that allows for a "Light-Touch" technique, essential for elderly patients or those with fragile skin. Each razor is produced in a temperature-controlled environment, ensuring that the lubricated coating remains stable and effective.

The handle design of our single-sided medical razor is the result of ergonomic research involving healthcare professionals. It features a unique "Ribbed-Control" grip that provides surgical nurses and assistants with maximum tactile feedback, even when wearing latex or nitrile gloves in wet conditions. The head design includes a specialized "Clog-Free" comb system. This integrated comb guides long or thick hair directly into the path of the blade, preventing the buildup of debris that often renders standard razors useless in emergency trauma situations. Furthermore, the material used in the handle is a high-impact, medical-grade polymer that is resistant to common clinical disinfectants, ensuring that no chemical leaching occurs during the prep process. We understand that in a hospital setting, cost-effectiveness is as vital as performance. By optimizing our high-speed automated production lines in Ningbo, we provide these professional-grade tools at a price point that supports the high-volume needs of public health systems and private clinics globally.

Beyond the physical tool, our commitment to medical excellence involves rigorous quality assurance. Every batch of razors undergoes localized stress testing to ensure the blade remains perfectly seated within the housing, even under the pressure of rapid pre-op preparation. Our 20,000 square meter facility is ISO certified, reflecting our dedication to international medical device standards. For distributors and hospital procurement officers, this razor offers the peace of mind that comes with a 30-year legacy of manufacturing reliability. We provide various sterilization options, including non-sterile bulk for general clinical use and specialized packaging for inclusion in sterile surgical kits. By choosing our medical prep series, you are investing in a product that prioritizes the patient’s comfort and the surgeon’s success. We continue to innovate in the field of clinical grooming, ensuring that every stroke is a step toward a safer, cleaner, and more efficient healthcare experience.

Ergonomic Design & Natural Texture

Specifications & Quick Facts

| Blade Material | Medical-Grade Swedish Steel |

| Handle Material | High-Impact Medical Polymer |

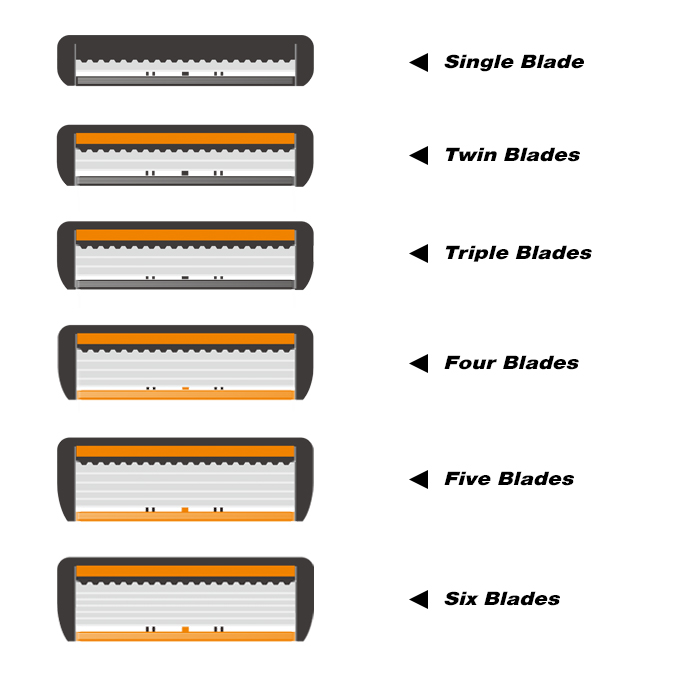

| Blade Configuration | Single Edge with Protective Comb |

| Sterility | Available Non-Sterile or EO Sterilized |

| Grip Type | Ribbed Non-Slip Professional Grip |

| Blade Coating | Anti-Friction Platinum & Chrome |

| Packaging Options | Bulk 100pcs/Box, Individual Pouch |

MOQ (Minimum Order)

100,000 PCSLead Time

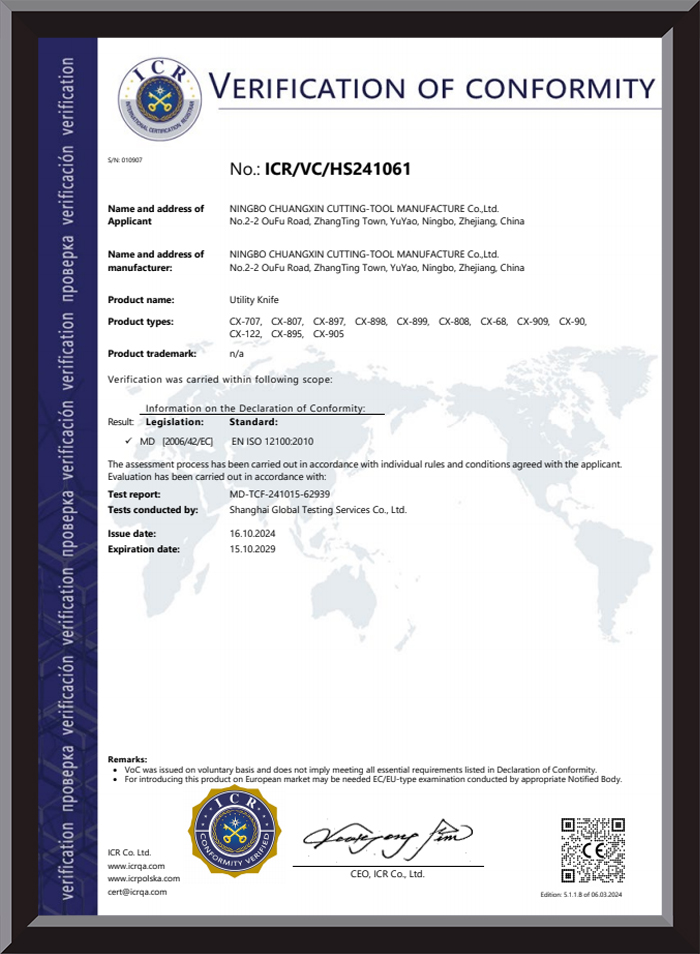

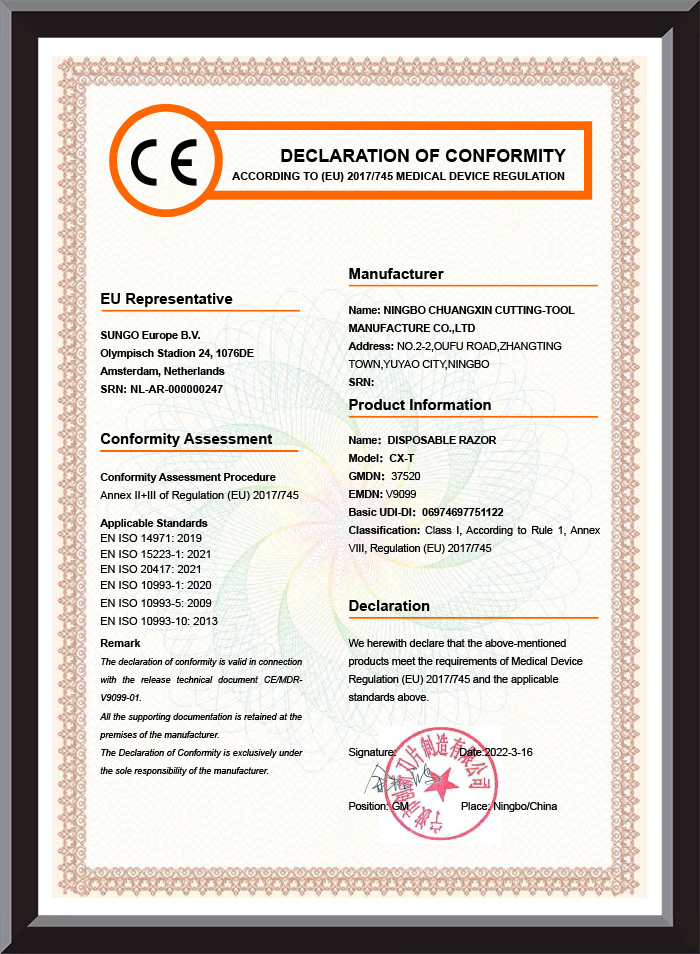

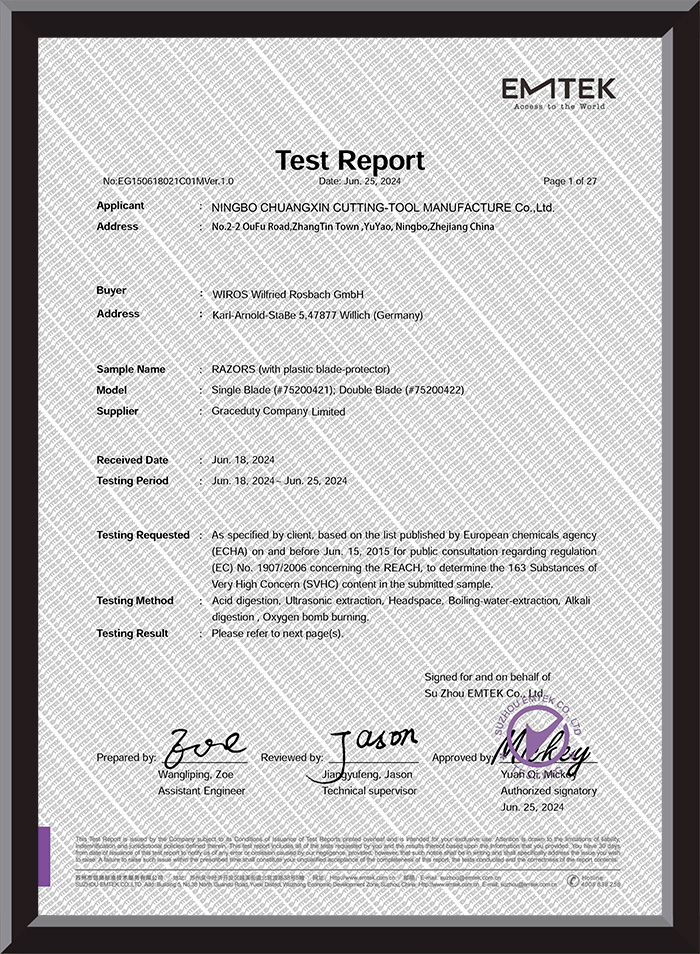

25-35 DaysCertifications

ISO13485, CE, FDA RegisteredPayment Terms

L/C, T/T, Trade AssuranceOur Customization Services

Comprehensive solutions tailored to your brand requirements

Need more customization options? Contact our engineering team for specialized solutions.

Why Choose Our Razor?

Key benefits for your business and customers

Infection Control

Designed to minimize micro-abrasions, significantly reducing SSI risks.

Clog-Free Comb

Integrated guide teeth prevent hair buildup for continuous, rapid prep.

Gloved Tactility

Handle texture optimized for secure use with latex and nitrile gloves.

Swedish Precision

Triple-honed edges ensure a clean shave with a single pass.

Bulk Efficiency

Available in high-volume packaging tailored for hospital logistics.

Hospital Grade

Compliant with international standards for medical device safety.

Application Scenarios

- General Surgical Pre-Operative Rooms

- Trauma and Emergency Departments

- Nursing Homes and Long-Term Care

- Clinical Laboratories and Diagnostic Centers

- Surgical Kit Assembly Manufacturers

Packaging Solutions

We offer Industrial Bulk Dispensers containing 100 units each for high-volume wards. For specialized needs, Individual Medical Pouches are available to maintain a clean-room standard. Custom labeling for hospital groups is provided.

Technical Details & Safety

Manufacturing Process

Produced in our Medical-Dedicated Molding Line, ensuring no cross-contamination. Blades are Laser-Inspected for edge consistency before being ultrasonic-cleaned and assembly.

- Cold-Stamping: Maintains the molecular integrity of the surgical steel.

- Automated Assembly: Reduces human contact for a more hygienic product.

- Quality Verification: Every 10,000th unit undergoes a pull-test and skin-simulant test.

Safety & Maintenance

- Discard immediately after single use in a designated biohazard sharps container.

- Do not reuse; intended for one patient only to prevent cross-infection.

- Inspect the protective comb for integrity before applying to sensitive skin.

- Store in a cool, dry place away from direct sunlight and chemicals.

Frequently Asked Questions

Yes, our medical polymers are specifically chosen to be compatible with Ethylene Oxide (EO) sterilization processes without degrading.

Absolutely. The integrated comb design allows for very fast prep even on long, matted hair in trauma situations.

When stored in original packaging, they have a functional shelf life of 5 years.

Yes, we can customize handle colors (e.g., blue for general, green for maternity) for large-scale hospital contracts.

This model features a fixed head to provide the maximum control required for precise clinical prep.

Yes, our medical prep razors are 100% latex-free to ensure patient and staff safety regarding allergies.

We provide full-box samples to qualified medical institutions and clinical distributors for evaluation.

The medical razor has a different blade angle and a comb guard to prevent micro-cuts that cause infections.

Yes, we maintain registrations for medical device exports to the US and European markets.

We use heavy-duty double-corrugated cartons to ensure the razors remain pristine during international sea freight.

Related Tags

Explore more insights and resources

English

English 中文简体

中文简体 русский

русский Español

Español