Anti Slip Grip Shaving Razors

Engineered for the shower. Features a triple-injected high-density TPV handle with a water-channeling cross-hatch grid for 100% slip-free control.

Related Products

Explore our sustainable product range

Product Introduction

Redefining personal care with circular economy principles

The Anti Slip Grip Shaving Razors are specifically engineered for the most demanding shaving environment: the hot, soapy shower. Safety in shaving is fundamentally linked to the stability of the tool, and this product line represents our most advanced solution for traction and control. For 30 years, our design team has worked on the Surface Friction Index, leading to the development of our proprietary Cross-Hatch Traction Grid. This pattern uses deep, water-channeling grooves that prevent the buildup of soap and water between the hand and the handle, maintaining a 100% secure grip. The handle is constructed using a Triple-Injected Elastomer process, which allows us to strategically place high-density rubber exactly where the fingertips and thumb exert the most pressure during a stroke.

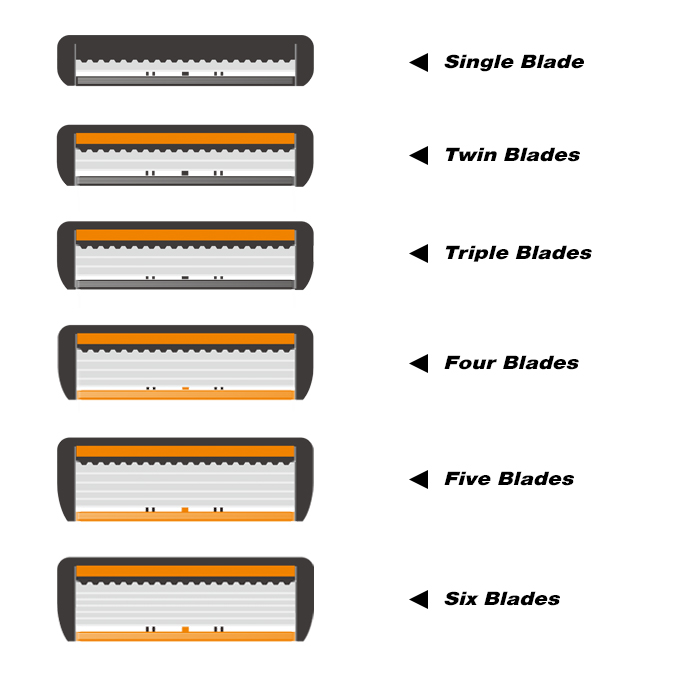

Technically, the "Grip-Zone" is made from a specialized Thermoplastic Vulcanizate (TPV) that offers superior resistance to bathroom chemicals and oils compared to standard rubbers. This ensures the handle never becomes slippery or "gummy" over time. The handle's ergonomic profile is slightly oversized, providing a larger surface area for the palm to engage with, which reduces the grip force required to maintain control—a key factor in preventing hand fatigue. The head features a multi-blade array (available in 3, 4, or 5 blades) with a high-flex pivot that complements the secure handle. This series is the perfect B2B solution for "Sports," "Active," or "Safety-First" grooming brands that want to emphasize ruggedness and reliability in their product storytelling.

For retail partners and private label brands, the Anti Slip Grip series offers a clear competitive advantage in the "Performance" segment. We provide a wide range of high-visibility color combinations, such as Neon Orange or Cobalt Blue, which emphasize the functional nature of the grip. Our manufacturing process in Ningbo utilizes state-of-the-art multi-cavity molds that ensure zero flash lines and perfect material bonding. By choosing our Anti Slip Grip series, you are offering your customers a razor that prioritizes their safety and control, ensuring a confident and irritation-free shave every time.

Ergonomic Design & Natural Texture

Specifications & Quick Facts

| Grip Technology | Cross-Hatch Water-Channeling Grid |

| Material | Triple-Injected TPV & Reinforced PP |

| Blade Compatibility | 3, 4, or 5 Blade Systems |

| Ergonomics | Oversized High-Traction Profile |

| Chemical Resistance | High (Resistant to Oils & Soap) |

| MOQ | 50,000 PCS |

| Testing Standard | ASTM Wet-Friction Certified |

Safety Index

High-Friction RatedLead Time

30-35 DaysQuality

Zero-Slip VerifiedOur Customization Services

Comprehensive solutions tailored to your brand requirements

Need more customization options? Contact our engineering team for specialized solutions.

Why Choose Our Razor?

Key benefits for your business and customers

Max Traction

Cross-hatch pattern ensures the grip stays secure even when covered in foam.

Water Drainage

Deep grooves channel water away from the hand to prevent sliding.

TPV Durability

High-grade elastomer resists bathroom chemicals and extreme humidity.

Fatigue Reduction

Oversized grip requires less hand pressure to maintain control.

Impact Resistant

Rugged build quality protects the razor from accidental drops.

Vibrant Branding

Multi-color injection allows for bold, high-contrast brand aesthetics.

Application Scenarios

- Active and Sports-Focused Grooming Brands

- Gym and Health Club Amenity Supply

- Outdoor Lifestyle and Camping Retailers

- Safety-Conscious Personal Care Lines

- Subscription Boxes for Active Men

Packaging Solutions

Available in Rugged Blister Packs, Waterproof Reusable Pouches, and High-Visibility Retail Display Units.

Technical Details & Safety

TPV Over-Molding

We use a Triple-Shot Injection Process where the TPV is molecularly bonded to the PP core, ensuring it cannot peel off under thermal stress.

- Wet-Friction Testing: Handles are tested on a tilted soap-water ramp.

- Tear Strength: TPV rubber is formulated for high resistance to nicks.

- Ergo-Scanning: Pressure-mapping used to optimize grip placement.

Maintenance & Care

- Rinse the handle after use to prevent soap-scum buildup in the grooves.

- Wiping the handle with a dry towel helps maintain the grip’s traction.

- Do not leave submerged in water for extended periods.

- Check the grip for signs of wear every few months.

Frequently Asked Questions

Related Tags

Explore more insights and resources

English

English 中文简体

中文简体 русский

русский Español

Español