Precision Ground Razor Blade

The gold standard in edge consistency. Precision-ground to sub-micron tolerances for surgical accuracy in professional and industrial applications.

Related Products

Explore our sustainable product range

Product Introduction

Redefining personal care with circular economy principles

The Precision Ground Razor Blade is the invisible force behind a perfect cut, whether in the grooming lounge or on the industrial finishing line. In the high-stakes world of precision tools, the "Grind" is everything. For 30 years, our Ningbo facility has operated at the intersection of traditional metallurgy and modern optical physics. A "Precision Ground" blade is defined by its consistency; unlike standard stamped edges, our blades undergo a Symmetric Double-Honing Process that ensures the cutting edge is perfectly centered within the steel's thickness. This eliminates "blade wander" and provides a predictable, repeatable cutting experience. We utilize ultra-fine grain stainless steel, which allows the grinding wheels to achieve a microscopic tip radius of less than 0.1 microns. This level of sharpness is essential for tasks where material displacement must be minimized, such as surgical preparation, high-end barbering, or precision laboratory sectioning.

Technically, our precision grinding utilizes Digital Feedback Systems to monitor the temperature and pressure of the grinding wheels in real-time. This prevents "Micro-Burn," a common defect in mass-produced blades that weakens the steel's molecular structure and leads to premature dulling. After the primary and secondary bevels are established, the blades are polished using chromium-oxide compounds to achieve a mirror finish. This reduces surface friction, allowing the blade to glide through fibers—be it hair or synthetic polymers—without snagging. To ensure long-term stability, we apply a Titanium-Nitride or Platinum coating, which acts as a protective shield against oxidation and wear. Our manufacturing process is strictly controlled under ISO 9001, and every production lot is subjected to laser-interferometry testing to verify that the edge geometry meets our 30-year internal standard for surgical-grade excellence.

For B2B medical suppliers, professional grooming brands, and industrial precision labs, our Precision Ground Razor Blades offer the reliability that high-spec environments demand. We understand that in your industry, a fraction of a millimeter can be the difference between success and failure. We offer extensive customization, including specialized edge angles (from 15 to 25 degrees) and custom coatings tailored to specific materials. Our factory-direct model provides the high-volume capacity required for global retail and industrial distribution, with the added benefit of our 30-year engineering heritage. By choosing our precision-ground series, you are partnering with a manufacturer that prioritizes the science of the edge above all else. We provide the technical depth, the manufacturing scale, and the quality assurance to ensure your products—and your brand—remain at the cutting edge of performance.

Ergonomic Design & Natural Texture

Specifications & Quick Facts

| Material | Ultra-Fine Grain Japanese/Swedish Stainless |

| Edge Radius | < 0.1 Microns (Surgical Grade) |

| Grind Type | Triple-Stage Symmetric Honing |

| Coating | Optional TiN, Platinum, or DLC |

| Hardness | 60-62 HRC |

| Thickness Tolerance | ±0.005mm |

| Surface Finish | Mirror Polished (Ra < 0.02) |

MOQ (Minimum Order)

200,000 PCSLead Time

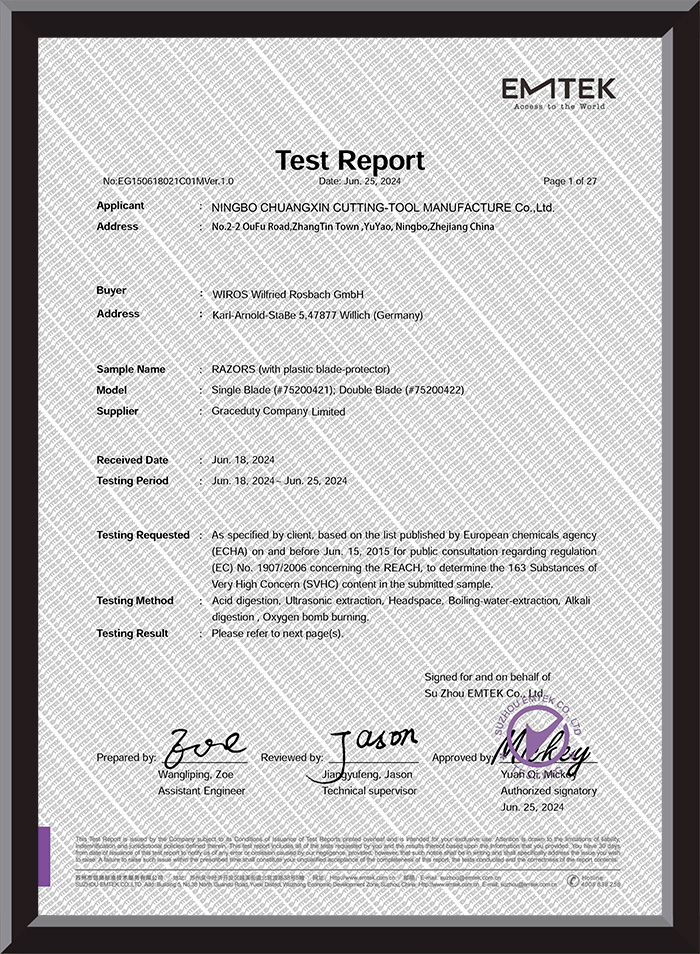

30-35 DaysCertifications

ISO9001, CE, FDA RegisteredPayment Terms

L/C, T/T, Trade AssuranceOur Customization Services

Comprehensive solutions tailored to your brand requirements

Need more customization options? Contact our engineering team for specialized solutions.

Why Choose Our Razor?

Key benefits for your business and customers

Zero Blade Wander

Perfectly centered edge ensures straight, predictable cuts every time.

Micro-Burn Free

Monitored grinding temperature preserves the steel's structural integrity.

Ultra-Glide Finish

Mirror polishing reduces drag and prevents material buildup.

Edge Stability

Triple-stage honing provides a robust base for a razor-sharp tip.

Consistent Sharpness

Automated optical inspection ensures every blade meets the spec.

Custom Geometry

Available in various bevel angles to suit specific industrial needs.

Application Scenarios

- Professional Master Barbering and Shaving

- Medical and Surgical Skin Preparation

- High-Precision Laboratory Material Slicing

- Industrial Film and Foil Slitting

- OEM Premium Grooming Kits

Packaging Solutions

We offer Anti-Static Safety Trays for industrial lines and Sterile Individual Blisters for medical/beauty use. Custom branded packaging is available for all B2B orders.

Technical Details & Safety

Manufacturing Process

Utilizes CNC Multi-Axis Grinding stations. The final hone is achieved using natural and synthetic diamond abrasives for a flawless edge.

- Interferometry Check: Laser measurement of edge symmetry.

- Surface Topography: SEM analysis of the coating uniformity.

- Degreasing: Ultrasonic cleaning to remove all manufacturing residues.

Safety & Maintenance

- Store in a temperature-controlled, dry environment to prevent condensation.

- Do not touch the edge with fingers; even natural oils can cause micro-corrosion.

- Use only with compatible precision handles to maintain edge alignment.

- Dispose of in dedicated sharps containers immediately after use.

Frequently Asked Questions

It means the very tip of the blade is thinner than a single micron, allowing it to cut through cells and fibers with minimal force.

Yes, we can adjust our CNC grinding parameters to meet your specific technical requirements.

Standard blades are "Clean Room" packed; gamma sterilization is available as an additional service.

Diamond-Like Carbon (DLC) is our toughest coating, providing extreme hardness and low friction for industrial use.

Our 100% automated optical inspection system scans every blade for edge nicks or irregularities.

Related Tags

Explore more insights and resources

English

English 中文简体

中文简体 русский

русский Español

Español