High Precision Thin Slitting Blade

The high-speed converting specialist. Ultra-thin, mirror-lapped blades made from Tungsten Carbide or PM Steel for zero-deflection slitting.

Related Products

Explore our sustainable product range

Product Introduction

Redefining personal care with circular economy principles

The High Precision Thin Slitting Blade is the specialized industrial solution for the high-speed conversion of delicate materials. In industries like flexible packaging, battery manufacturing, and medical film production, the thickness and edge quality of the slitting blade directly determine the "edge-yield" and the amount of waste generated. For 30 years, our Ningbo factory has specialized in Ultra-Thin Blade Technology, producing edges as thin as 0.10mm that maintain perfect flatness under high-speed rotation or longitudinal tension. Unlike standard utility blades, slitting blades must operate with zero lateral deflection; any "flutter" in the blade will result in a jagged edge or a damaged roll of expensive material. We utilize high-purity Tungsten Carbide or Powder-Metal (PM) Steels, which offer the extreme rigidity required to maintain a straight cut even at web speeds of over 500 meters per minute.

Technically, our thin slitting blades are manufactured using a process of Creep-Feed Grinding and Lapping. The blade faces are lapped to a mirror-like Ra 0.05 finish, which is critical for reducing "material drag." If the blade surface is rough, it generates heat and friction, which can melt thin plastic films or cause "burring" on aluminum foil. Our blades feature a Variable Bevel Geometry, allowing us to tailor the edge to the specific material being slit—whether it's an abrasive lithium-ion battery separator or a delicate multi-layer medical laminate. To combat the abrasive wear typical in paper and non-woven industries, we apply specialized coatings like Diamond-Like Carbon (DLC) or Boron-Carbide, which can extend the blade's life by up to 10 times compared to untreated steel. Every blade is checked for flatness using optical flat testing, ensuring that across a 100mm diameter, the deviation is less than 0.002mm.

For industrial converter suppliers, battery manufacturers, and MRO distributors, our High Precision Thin Slitting Blades offer a high-performance alternative to expensive European or Japanese brands. We provide the technical expertise to analyze your specific material challenges and suggest the optimal metallurgy and edge profile. Our factory-direct model allows for the high-volume production of custom sizes, with the added benefit of our 30-year legacy in industrial edge science. We understand the high cost of downtime in a conversion facility; therefore, we maintain strict quality control to ensure that every replacement blade performs exactly like the first. Choosing our slitting series means investing in a cleaner cut and higher production yields. We provide the manufacturing precision, the advanced materials, and the technical support to help your facility—or your customers' facilities—operate at peak efficiency. We don't just sell blades; we sell cutting performance.

Ergonomic Design & Natural Texture

Specifications & Quick Facts

| Material | Tungsten Carbide / Powder Metal Steel |

| Thickness | 0.10mm to 0.40mm Ultra-Thin Range |

| Flatness Tolerance | < 0.002mm Across Surface |

| Surface Roughness | Ra < 0.05 (Mirror Lapped) |

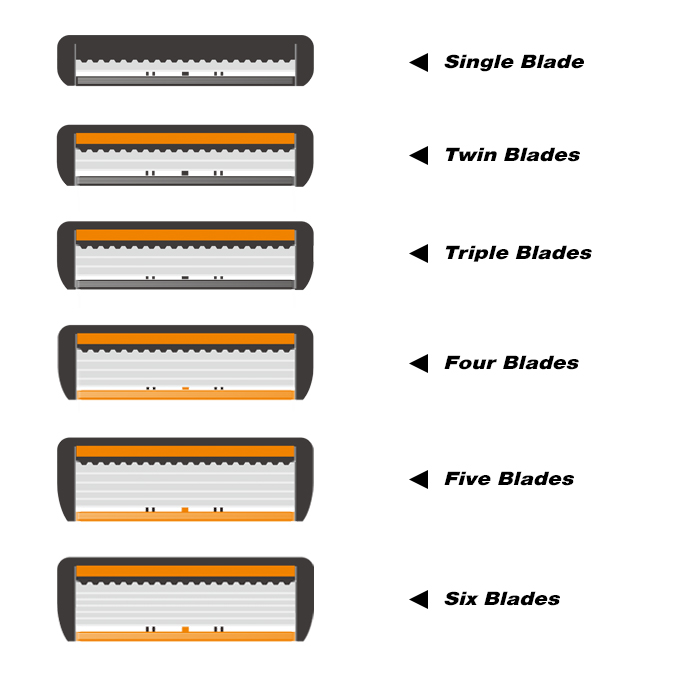

| Edge Type | Custom Bevel (Single/Double/Asymmetric) |

| Coating | DLC, TiAlN, or Boron-Carbide |

| Hardness | Up to 92 HRA (Carbide) / 68 HRC (Steel) |

MOQ (Minimum Order)

1,000 PCSLead Time

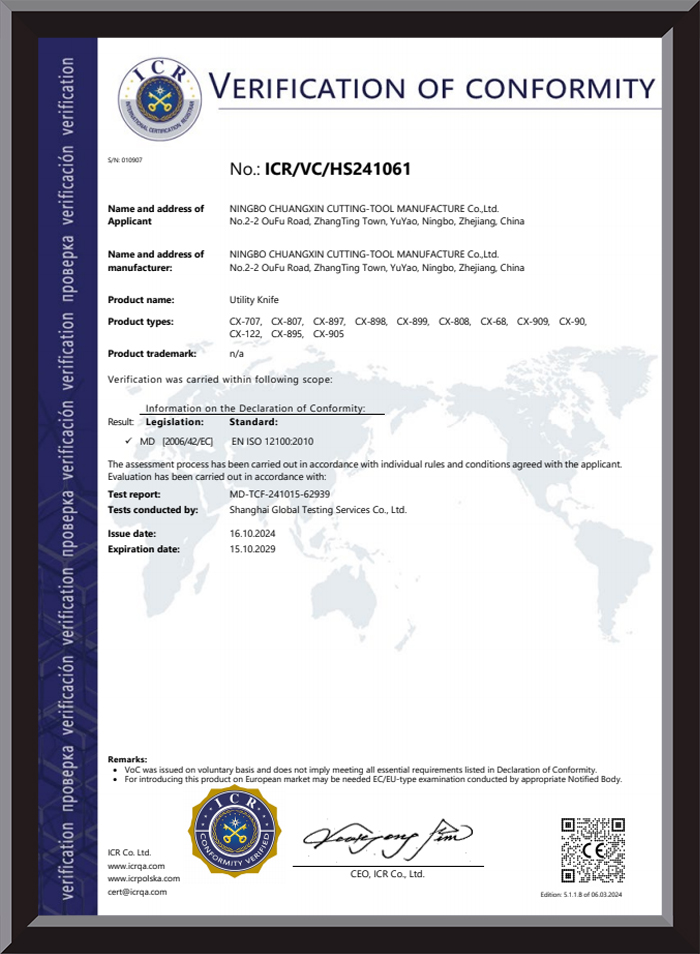

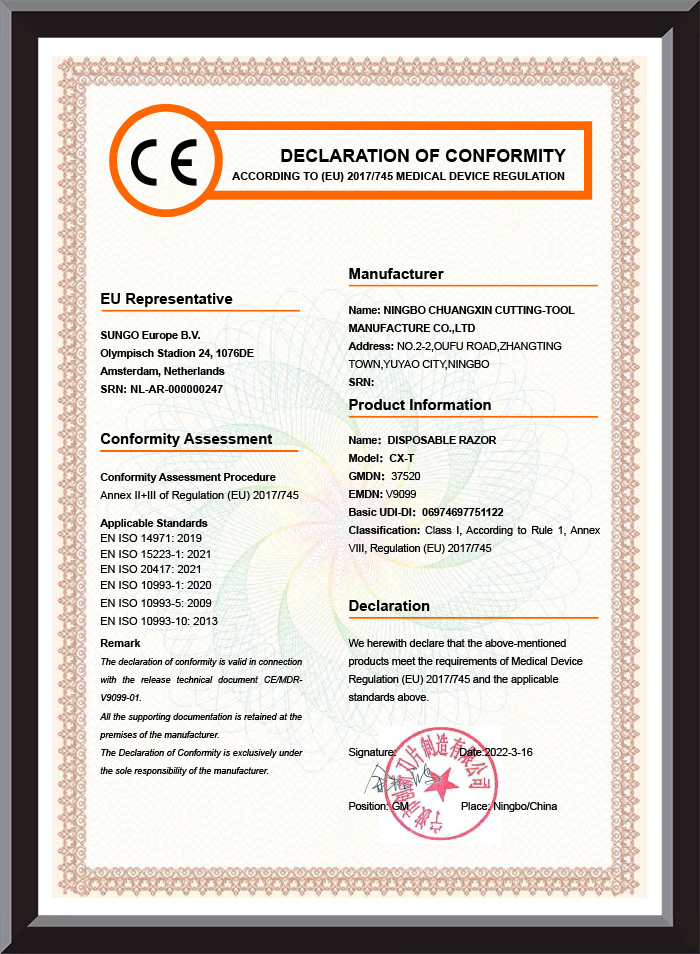

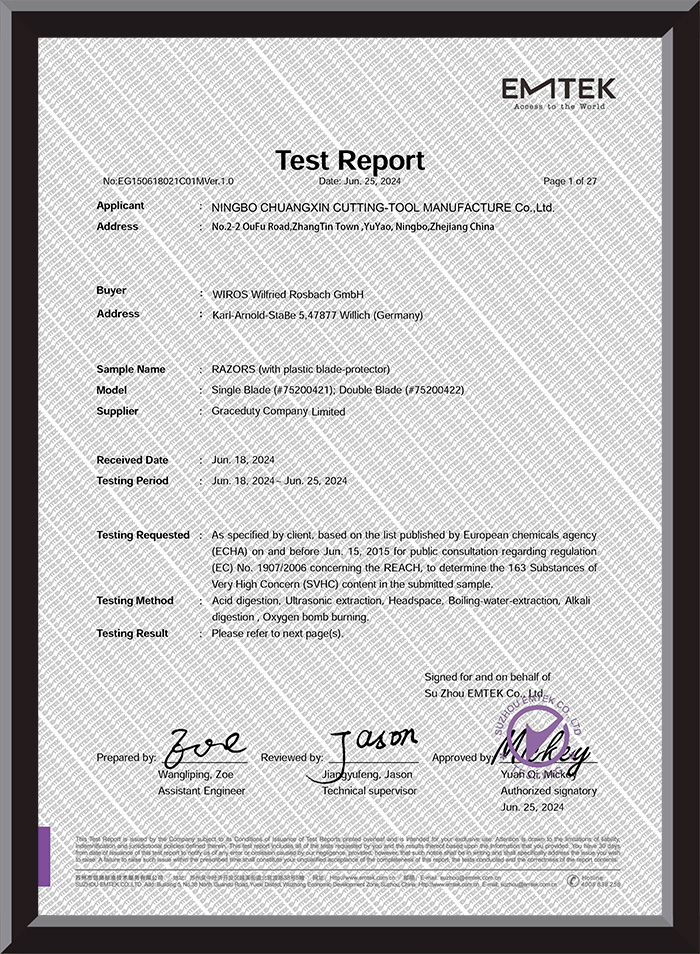

25-30 DaysCertifications

ISO9001, REACH, ROHSPayment Terms

T/T, L/C, Trade AssuranceOur Customization Services

Comprehensive solutions tailored to your brand requirements

Need more customization options? Contact our engineering team for specialized solutions.

Why Choose Our Razor?

Key benefits for your business and customers

Zero Material Drag

Mirror-lapped faces prevent adhesive buildup and material tearing.

Ultra-Rigidity

Tungsten carbide construction eliminates blade flutter at high speeds.

Zero-Burr Finish

Precision-honed edges provide clean cuts on delicate foils and films.

Extended Run Life

Advanced coatings reduce wear, leading to fewer blade changes.

Extreme Flatness

Maintains a consistent slitting width across miles of material.

Material Specific

Tailored edge angles for everything from PET to copper foil.

Application Scenarios

- Lithium-Ion Battery Separator and Foil Slitting

- Flexible Packaging and Plastic Film Conversion

- Medical Grade Adhesive and Tape Slitting

- Precision Non-Woven and Textile Trimming

- High-Speed Paper and Label Converting

Packaging Solutions

We offer High-Impact Protective Cases with oil-impregnated liners to prevent oxidation. Bulk industrial packs are available with vacuum-sealed vapor barrier bags.

Technical Details & Safety

Manufacturing Process

Produced via HIP (Hot Isostatic Pressing) for carbide blades. Final edges are finished on high-precision peripheral grinders with 40,000 RPM spindles.

- Flatness Optical Check: Verified by Newton fringes under monochromatic light.

- Edge Radius SEM: Scanning Electron Microscope check for edge crispness.

- Dynamic Balancing: Ensures no vibration in circular slitting applications.

Safety & Maintenance

- Handle with extreme care; these blades are fragile if dropped (Carbide).

- Clean with non-abrasive solvents to remove adhesive residue between runs.

- Always use precision-ground spacers and collars for mounting.

- Replace immediately if microscopic "nicking" is detected to avoid roll waste.

Frequently Asked Questions

Carbide is much stiffer and harder, allowing for longer runs and more precise cuts on abrasive materials.

Yes, we can perform a metallurgical and geometric analysis of any sample to match or exceed its performance.

We can produce stable slitting blades down to 0.10mm for specialized medical applications.

Yes, it significantly reduces the friction that causes material deformities and "dust" during slitting.

Custom industrial blades typically require 25 to 30 days for precision grinding and coating.

Related Tags

Explore more insights and resources

English

English 中文简体

中文简体 русский

русский Español

Español