High Carbon Steel Replacement Blades

The professional standard for industrial edge-retention. High-carbon SK5 steel blades, precision-ground and double-honed for extreme durability.

Related Products

Explore our sustainable product range

Product Introduction

Redefining personal care with circular economy principles

The High Carbon Steel Replacement Blades serve as the sharp beating heart of any professional cutting operation. In the world of industrial manufacturing and heavy-duty construction, the blade is often more critical than the handle it sits within. For 30 years, our Ningbo facility has perfected the science of carbon steel metallurgy. Unlike standard stainless steel, our high-carbon SK5 steel undergoes a proprietary multi-stage heat treatment process. This creates a blade with a hardness level exceeding 60 HRC (Rockwell Scale), providing the "edge-holding" capability that professional tradespeople demand. When cutting abrasive materials like triple-wall corrugated cardboard, heavy rubber, or asphalt shingles, a standard blade would dull in minutes. Our high-carbon series is engineered to maintain its microscopic tooth geometry significantly longer, reducing the frequency of blade changes and directly increasing workplace productivity. The secret lies in our Double-Honed Edge, which provides a clean, surgical initial cut followed by a robust secondary bevel that resists chipping under high lateral pressure.

Technically, these blades are a marvel of precision manufacturing. Each blade is stamped from cold-rolled steel coils, then precision-ground using automated CNC machinery that maintains a tolerance of less than 0.01mm. To combat the brittleness often associated with high-carbon steel, we employ a Vacuum Tempering process that balances extreme hardness with enough fracture toughness to prevent the blade from shattering under sudden impact. This makes them significantly safer in high-speed industrial environments. Furthermore, each blade is finished with a light layer of vapor-phase corrosion inhibitor (VCI) oil, ensuring they remain in pristine, rust-free condition even after months of storage in humid warehouse environments. The universal geometry ensures they fit 99% of standard utility knives globally, making them the ultimate B2B "consumable" for hardware retailers and industrial supply houses. Our massive production capacity allows us to produce millions of these blades monthly, ensuring that we can support even the largest national procurement contracts with consistent, high-quality supply.

For industrial distributors and global tool brands, our High Carbon Steel Replacement Blades represent a high-margin, high-volume recurring revenue stream. We understand that quality consistency is paramount; therefore, every single batch undergoes a "CATRA" edge-retention test to verify it meets our 30-year internal benchmark. We offer extensive customization for B2B partners, including Laser-Etched Branding directly on the steel and custom blade dispensers designed for safety and speed. Whether you are supplying a major construction firm or a global DIY retail chain, our blades provide the professional-grade performance that builds customer loyalty. Choosing our SK5 series means investing in a legacy of metallurgical excellence. We provide the manufacturing scale, the technical precision, and the logistical reliability to keep your customers' tools sharp and their projects moving forward. Our commitment to quality is your guarantee that every cut will be as sharp as the first.

Ergonomic Design & Natural Texture

Specifications & Quick Facts

| Material | SK5 High-Carbon Industrial Steel |

| Hardness | 60-62 HRC (Rockwell) |

| Edge Type | Double-Bevel Surgical Hone |

| Compatibility | Universal Large Utility Knife Fit |

| Thickness | 0.50mm / 0.60mm Professional Gauge |

| Finish | VCI Anti-Rust Oil Coating |

| Batch Testing | CATRA Edge Retention Certified |

MOQ (Minimum Order)

100,000 PCSLead Time

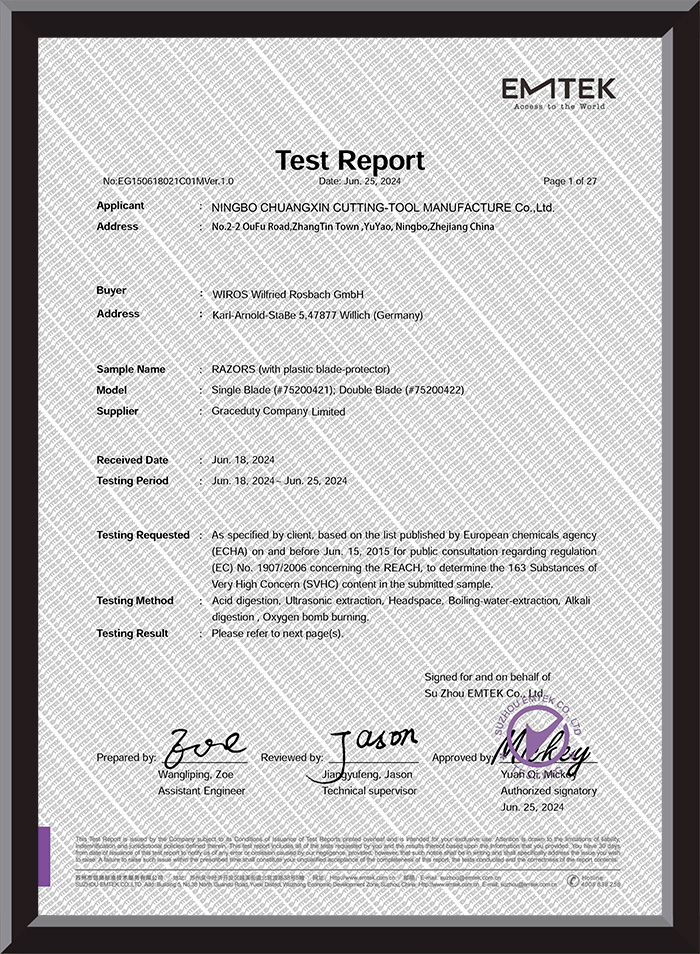

20-25 DaysCertifications

ISO9001, REACH, ROHSPayment Terms

T/T, L/C, Trade AssuranceOur Customization Services

Comprehensive solutions tailored to your brand requirements

Need more customization options? Contact our engineering team for specialized solutions.

Why Choose Our Razor?

Key benefits for your business and customers

3X Life Span

Lasts up to three times longer than standard utility blades.

High Fracture Toughness

Vacuum tempering prevents blades from shattering under load.

Universal Fit

Standard geometry fits all global major utility knife brands.

Cleanest Cuts

Double-honing reduces friction and prevents material tearing.

Rust Protected

VCI coating ensures blades arrive sharp and stays sharp in storage.

Bulk Margin

High-volume production provides unbeatable factory pricing.

Application Scenarios

- Heavy-Duty Construction and Drywalling

- Large-Scale Warehouse and Logistics Fulfillment

- Automotive and Industrial Gasket Manufacturing

- Professional Flooring and Carpet Installation

- High-Volume DIY Retail Supply

Packaging Solutions

We provide Safety Dispensers (10, 50, or 100-pack) that allow for tool-free, one-at-a-time blade extraction. Bulk Wrapped Packs are available for industrial manufacturing lines.

Technical Details & Safety

Manufacturing Process

Produced via Continuous Induction Hardening. Each blade edge is inspected using high-speed optical sensors to detect any microscopic imperfections.

- Decarburization Control: Maintains carbon integrity during heating.

- Automated Grinding: Maintains exact bevel angles for consistent cutting.

- Force Testing: Every batch tested for tip strength and bending resistance.

Safety & Maintenance

- Always use the safety dispenser to remove a single blade.

- Never leave used blades loose; dispose of them in a puncture-proof bin.

- Ensure your knife handle's locking mechanism is secure before cutting.

- A dull blade is dangerous; replace at the first sign of dragging or tearing.

Frequently Asked Questions

Yes, our blades are manufactured to universal standards and fit almost all professional utility knives.

SK5 is the industry standard for high-end blades; SK2 has even higher carbon content for extreme industrial use.

Yes, we apply a thin VCI oil layer to prevent corrosion during international shipping and storage.

Yes, for orders over 100,000 units, we offer custom laser-etching on the blade body.

Most of our dispensers have a "Used Blade" slot in the back for safe, integrated disposal.

Related Tags

Explore more insights and resources

English

English 中文简体

中文简体 русский

русский Español

Español