We are an industry and trade enterprise

specializing in the production of disposable razors and utility knives for more than 30 years.

Knife News

Utility Knife vs. Box Cutter: Which Tool is Right for You

Content

- 1 What is a Utility Knife?

- 2 What is a Box Cutter?

- 3 Key Differences Between Utility Knives and Box Cutters

- 4 Comparison Table: Utility Knife vs. Box Cutter

- 5 When to Use a Utility Knife

- 6 When to Use a Box Cutter

- 7 Safety Tips for Both Tools

- 8 If you are looking for cost-effective disposable solutions, check our latest collection.

A utility knife is a versatile cutting tool designed for general manual work, while a box cutter is a cutting tool primarily designed for opening boxes and packages.

What is a Utility Knife?

A utility knife is a versatile cutting tool designed for general manual work. It is commonly used for cutting a variety of materials, including cardboard, drywall, carpet, and other heavy-duty materials. They are also popular for crafting and DIY projects that require precision and a durable blade.

Types of Utility Knives

- Fixed blade utility knives

These knives have a blade that is permanently or securely locked in a non-retractable position.

- Advantages: Offers maximum stability and strength for heavy-duty cutting tasks. The blade is less likely to break or retract under pressure.

- Disadvantages: The exposed blade requires a sheath or cover for safe storage and transport.

- Retractable blade utility knives

The blade on these knives can be extended for use and fully retracted into the handle for safety.

- Advantages: Safer to carry and store. The blade can be adjusted to different cutting depths.

- Disadvantages: The retractable mechanism can be less durable for the most demanding tasks, and the blade may be slightly less stable than a fixed blade.

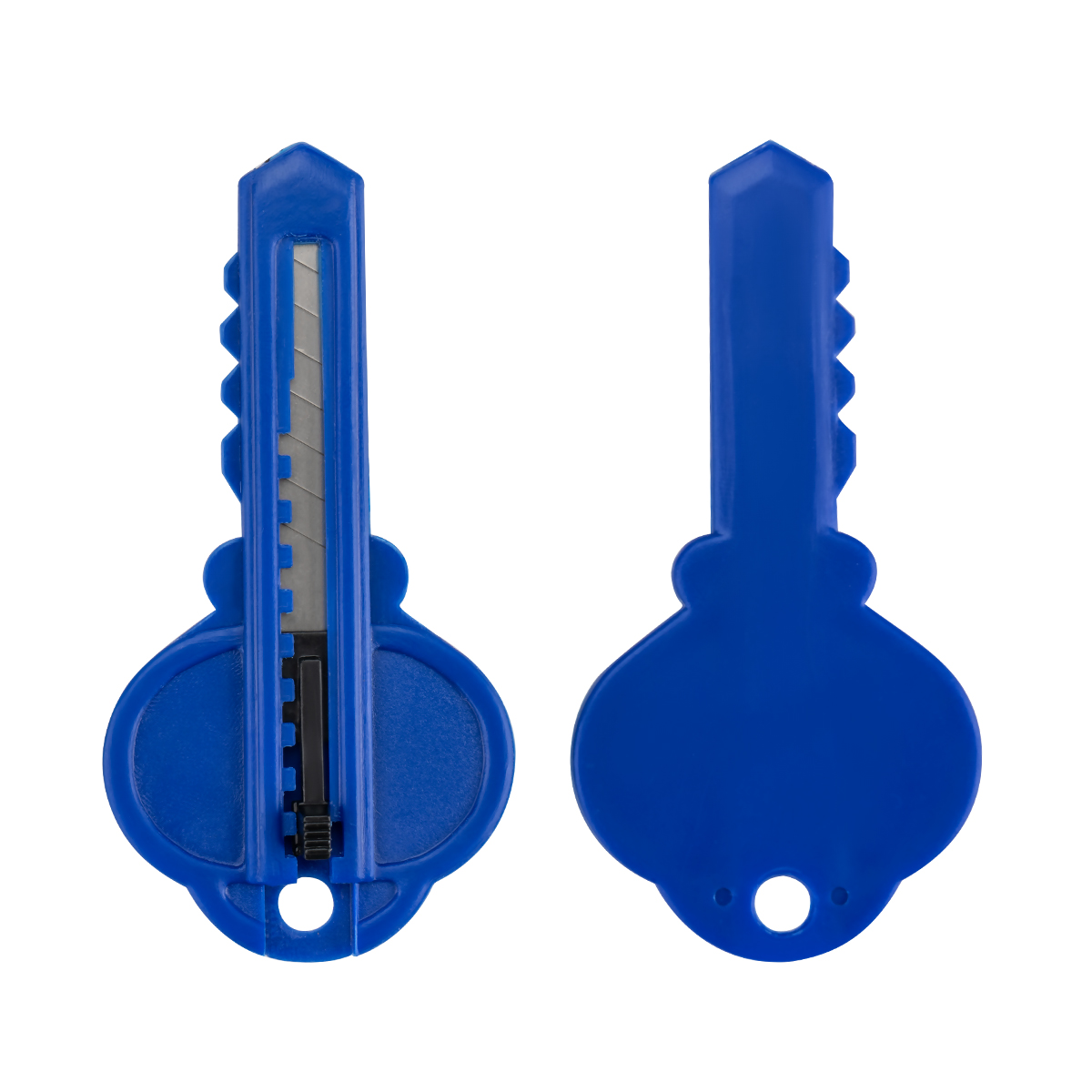

- Folding utility knives

These knives have a blade that folds into the handle like a pocket knife.

- Advantages: Compact and easy to carry in a pocket or on a belt. Offers the safety of a retractable blade with the portability of a folding knife.

- Disadvantages: The hinge mechanism can be a point of weakness compared to fixed or retractable models, and they may be less suited for continuous, heavy-duty use.

Advantages of Utility Knives

- Versatility: Can handle a wide range of materials and tasks, from light cutting to tough, heavy-duty jobs.

- Sturdier construction: Generally built with a more robust handle and a thicker, stronger blade, making them ideal for professional or industrial use.

Disadvantages of Utility Knives

- Can be bulkier: The sturdy construction often means they are larger and heavier than box cutters.

- Blade changes may require tools: Some models may require a screwdriver or other tool to change the blade, which can be less convenient than a tool-free design.

|

|

What is a Box Cutter?

A box cutter is a cutting tool primarily designed for opening boxes and packages. They are typically used for light-duty cutting tasks, such as slicing through tape, plastic wrap, and thin cardboard.

Types of Box Cutters

- Standard box cutters

These are the most common type, featuring a simple handle with a fixed or retractable blade.

- Advantages: Lightweight, easy to use, and widely available.

- Disadvantages: The blade may not be as durable as a utility knife blade, and the handle can be less ergonomic for prolonged use.

- Safety box cutters

These are designed with enhanced safety features to minimize the risk of injury.

- Advantages: Often have a mechanism that automatically retracts the blade when it loses contact with the cutting surface. Some models have a guarded or shrouded blade to prevent accidental contact.

- Disadvantages: The guarded design can limit the cutting depth and may not be suitable for all tasks.

Advantages of Box Cuters

- Lightweight and easy to handle: Their compact and light design makes them comfortable for quick, repetitive tasks like opening many boxes.

- Often feature automatic blade retraction for safety: Many box cutters have a spring-loaded mechanism that retracts the blade as soon as the user's thumb is released, significantly reducing the risk of accidental cuts.

Disadvantages of Box Cutters

- Not suitable for heavy-duty cutting: The thinner blade and lighter construction are not designed for cutting thick or dense materials like drywall or carpet. Attempting to do so can break the blade or damage the tool.

- Blades can be less durable: The thinner blades of a box cutter can dull or snap more easily than the thicker blades of a utility knife, especially when used on materials they are not intended for.

Key Differences Between Utility Knives and Box Cutters

Blade Design and Strength

- Utility Knife Blades:

- Thickness: Generally thicker, often between 0.024 and 0.035 inches.

- Strength: Designed to be rigid and strong to handle tough materials without bending or breaking.

- Shape: Typically have a trapezoidal or hooked shape, allowing for deep, powerful cuts.

- Box Cutter Blades:

- Thickness: Thinner, often around 0.016 inches.

- Strength: More flexible and prone to snapping under heavy pressure.

- Shape: Usually a simple, rectangular shape, optimized for slicing and piercing.

Safety Features

- Utility Knives:

Safety features often include locking mechanisms that secure the blade in place to prevent accidental retraction or extension. Some models have a thumb-operated slider for blade adjustment. Fixed-blade versions require a separate sheath for safety.

- Box Cutters:

A primary focus of design is on user safety. Many models feature a spring-loaded, automatic blade retraction system. Others may have a guarded blade or a "shrouded" design that only exposes the very tip of the blade, minimizing accidental contact.

Ergonomics and Handling

- Utility Knives:

Handles are typically more substantial and contoured to provide a firm, comfortable grip for long-term use and heavy-duty tasks. Often have a weightier feel, which can add stability and control during deep cuts.

- Box Cutters:

Handles are generally lighter and more compact. The design prioritizes ease of handling and quick, repetitive use rather than sustained pressure or heavy-duty leverage.

Common Uses

- Utility Knives:

Designed for heavy-duty cutting, such as cutting drywall, insulation, and carpet; slicing through thick rubber, rope, and vinyl; opening heavy shipping containers or reinforced cartons.

- Box Cutters:

Designed for light-duty, quick cuts, such as opening cardboard boxes and packages; slicing through packing tape, plastic wrap, and shrink wrap; cutting paper or thin materials for crafts.

Comparison Table: Utility Knife vs. Box Cutter

| Feature | Utility Knife | Box Cutter |

|---|---|---|

| Primary Use | Heavy-duty cutting, construction, and DIY projects | Light-duty cutting, opening boxes and packages |

| Blade Thickness | Thicker and more durable (e.g., 0.024-0.035 in.) | Thinner and more flexible (e.g., ~0.016 in.) |

| Blade Shape | Trapezoidal or hook-shaped | Simple rectangular, sometimes snap-off |

| Safety Features | Locking mechanisms, fixed blades, folding designs | Automatic blade retraction, guarded blades, shrouds |

| Materials Cut | Drywall, carpet, insulation, tough plastics, rope | Cardboard, packing tape, plastic wrap, shrink wrap |

| Ergonomics | Substantial, ergonomic handles for a firm, sustained grip | Lightweight and compact for quick, repetitive tasks |

| Blade Change | May require a tool (older models) or feature a tool-free design | Often a simple, quick-change or snap-off system |

| Durability | Built for heavy use and longevity | Designed for lighter, more frequent blade replacement |

| Portability | Often larger and heavier; sometimes folding for transport | Generally smaller, lighter, and easier to carry in a pocket |

When to Use a Utility Knife

- For Construction and Renovation Projects: A utility knife is the ideal tool for tasks that require cutting through thick or dense materials. Its strong blade and sturdy handle provide the necessary leverage and control for jobs like cutting drywall, insulation, roofing shingles, and carpeting.

- When Cutting Tough Materials: If your task involves cutting materials that would easily snap or dull a thinner blade, such as heavy-gauge plastic, thick rubber, or dense rope, a utility knife is the more reliable choice.

- For Precision in DIY: Many DIY enthusiasts and crafters use utility knives for their projects because the rigid blade allows for precise cuts in materials like foam core board, thick paper, or leather.

When to Use a Box Cutter

- For Opening Boxes and Packages: This is the primary function of a box cutter. Its design allows for quick, safe slicing of packing tape and cardboard without the risk of damaging the contents inside.

- For Cutting Thin Materials: Box cutters are perfect for tasks involving lightweight materials. They excel at slicing through shrink wrap, plastic packaging, paper, and bubble wrap.

- In Retail or Warehouse Environments: Due to their lightweight nature and safety features like automatic blade retraction, box cutters are the go-to tool for employees who need to quickly and safely open a large volume of boxes.

Safety Tips for Both Tools

General Safety Precautions:

- Always Use a Sharp Blade: A dull blade requires more force to cut, increasing the risk of the blade slipping and causing injury. Change the blade as soon as it shows signs of dullness.

- Cut Away from Yourself: Always position the material so you are cutting away from your body. This simple rule is the most effective way to prevent a serious cut if the blade slips.

- Wear Gloves and Eye Protection: Gloves can provide a layer of protection against minor slips, while eye protection guards against flying debris or snapping blades.

- Store Tools Safely: When not in use, ensure the blade is fully retracted or the tool is placed in a protective sheath. Store tools in a secure location where they are out of reach of children.

Specific Safety Tips:

- Utility Knife:

- Always ensure the blade is locked securely in place before starting to cut.

- When changing a blade on a fixed or retractable utility knife, use extreme caution and, if required, follow the manufacturer's instructions for the tool-free or screw-based mechanism.

- Box Cutter:

- Rely on the automatic retraction feature. After each cut, release your thumb to allow the blade to retract automatically. Do not rely on manual retraction alone.

- Be mindful of the cutting depth, especially with snap-off blades, to avoid damaging the contents of a box.

- When snapping off a dull blade segment, use a tool or a built-in snip-off feature on the handle and point the blade away from your body.

If you are looking for cost-effective disposable solutions, check our latest collection.

![]() No. 2-2, Oufu Road, Zhangting Town, Yuyao City, Ningbo City, Zhejiang, China.

No. 2-2, Oufu Road, Zhangting Town, Yuyao City, Ningbo City, Zhejiang, China.

![]() +86-574-87560886/87560055

+86-574-87560886/87560055

![]() +86-574-87560885

+86-574-87560885

Copyright © Ningbo Chuangxin Cutting-Tool Manufacture Co., Ltd.

English

English 中文简体

中文简体 русский

русский Español

Español